A little help please with an annoying exhaust leak.. pictures

#1

Registered User

Thread Starter

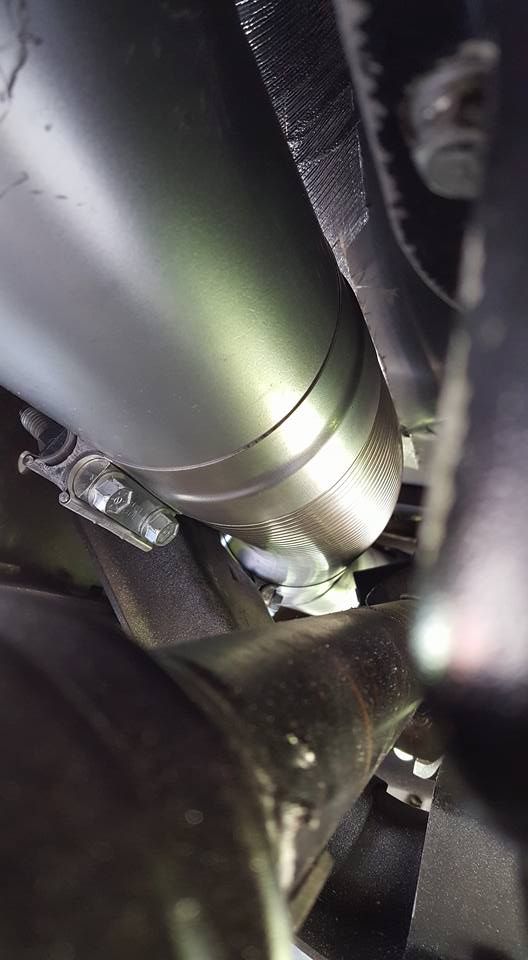

A little help please with an annoying exhaust leak.. pictures

Looks like I've got an exhaust leak at the turbine to downpipe. The book I have doesn't list a gasket for that connection. I have read there is a gasket. And different clamps that work. Before I tear into it can anyone give me some advice on getting this exhaust leak stopped?

It is also rattling just a bit. I have tried to tighten the clamp to no avail.

It is also rattling just a bit. I have tried to tighten the clamp to no avail.

#2

Registered User

I had a similar problem with my 93. On mine there was no gasket at the break. There is a 90 degree flange on the pipe underneath the clamp that mates to another face on the turbo and is tightened and held in place by the clamp.

The flange on the downpipe was cracked all the way around the flange so that it could not be tightnened enough to prevent the exhaust leak. It cracked because the tailpipe was hard mounted to the flatbed by a strap steel hanger.

You need the rubberized plastic exhaust hangers for your exhaust pipe otherwise the exhaust system vibration will cause the flange to crack. I had to replace 2 downpipes before I figured out what the issue was !

Check your exhaust system and make sure it has the proper hangers in place and is not "hard mounted" anywhere.

The flange on the downpipe was cracked all the way around the flange so that it could not be tightnened enough to prevent the exhaust leak. It cracked because the tailpipe was hard mounted to the flatbed by a strap steel hanger.

You need the rubberized plastic exhaust hangers for your exhaust pipe otherwise the exhaust system vibration will cause the flange to crack. I had to replace 2 downpipes before I figured out what the issue was !

Check your exhaust system and make sure it has the proper hangers in place and is not "hard mounted" anywhere.

#3

Registered User

I had a 95 CTD with a similar problem. It leaked around the V band clamp that held the down pipe to the turbine housing. I ended up replacing the clamp and it stopped the leak/rattle. The clamp looks pretty tight in the pics. May be worn out or over tightened and distorted.

#4

Registered User

Thread Starter

well, I pulled it today and there was a crack right at the connection. I had to go to a muffler shop and have them swedge out a piece in order for me to TIG weld it in place. It turns out there is only one stabilizing bracket on the entire muffler system! In the back. I have get under there and figure out how to weld in a few spots to hold that muffler and downpipe in place.

Is there a good source for these clamps on line? I have welded few things in the past for a few pilots and I have seen those clamps used in some aircraft.

Is there a good source for these clamps on line? I have welded few things in the past for a few pilots and I have seen those clamps used in some aircraft.

#5

1st Generation Admin

In order to prevent that crack at the turbo's V-band clamp, Dodge put a somewhat resilient mount at the transmission bellhousing. This prevents the engine twist from breaking the pipe at the flange.

I've got one on my mess (custom downpipe).

Any torsional flex and such is addressed in my mess with a 12" piece of SS flex just downstream . . .

I've got one on my mess (custom downpipe).

Any torsional flex and such is addressed in my mess with a 12" piece of SS flex just downstream . . .

The following 2 users liked this post by BC847:

mknittle (12-11-2017),

thrashingcows (12-11-2017)

#6

Registered User

Thread Starter

YES! Just what I needed was a pic of that. Thanks for that!. Mine has no bracket on it but I can quickly fab and weld one on to catch that bell housing bolt.

It's kinda hard to see on that pic which bell housing bolt that is..

Also, I might have to take a torch to the back of the muffler. Heat it up and hammer a little flat spot on it. Mine in the back is hitting the leaf spring pack

It's kinda hard to see on that pic which bell housing bolt that is..

Also, I might have to take a torch to the back of the muffler. Heat it up and hammer a little flat spot on it. Mine in the back is hitting the leaf spring pack

The following users liked this post:

BC847 (12-06-2017)

#7

Registered User

Facing towards the front of the truck, looking at the trans it should be the lowest bolt on the right side. Dodge had a factory bracket there. I was thinking that the pipe might be cracked at the v band flange b/c it looked like there was a little smudge of soot on it in your pic that was in an abnormal place.

Trending Topics

#8

Registered User

Thread Starter

that will work. I have a few pipe mounts off of an older Toyota pickup that I can weld on to catch that bolt.

Now comes securing that pipe and muffler. Right now it is very poorly secured under there. I am going to have to put on my thinking hat tomorrow . It's going to be tricky with this 4" very long pipe.

Now comes securing that pipe and muffler. Right now it is very poorly secured under there. I am going to have to put on my thinking hat tomorrow . It's going to be tricky with this 4" very long pipe.

#9

1st Generation Admin

This is the OEM exhaust downpipe to trans bellhousing mount. It has a rubber insert to dampen the noise via mechanical decoupling. A band-clamp holds it to the pipe.

That bolt right there . . .

That bolt right there . . .

#11

Registered User

Thread Starter

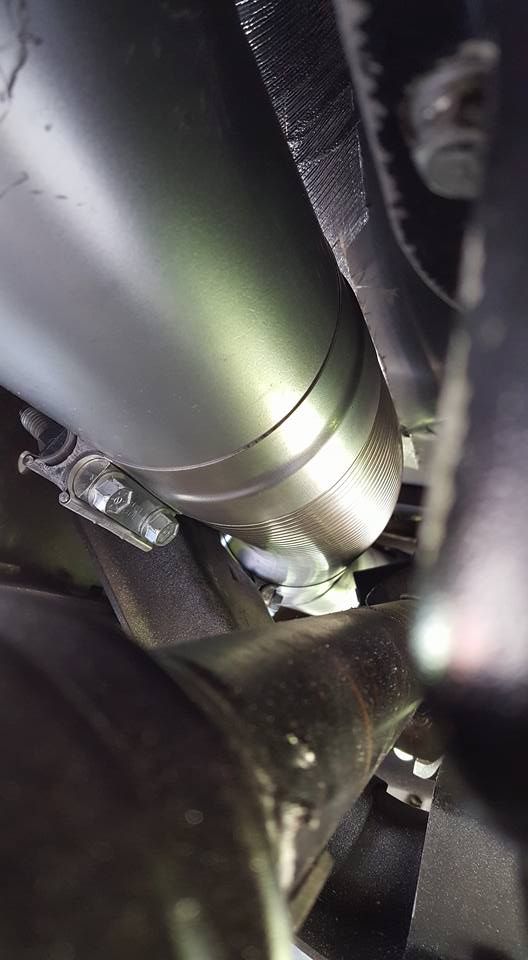

Here is the fix on my junk..

I had to have a local muffler shop double up two pipes and swedge them out to make the lip thicker on the end of the downpipe. According to a diesel buddy of mine this mimics the correct factory spec. making an exhaust leak or break at the turbine less likely.

I then TIG'ed the connection. The other photo is the bracket I modified that came off a toyota downpipe bracket. I MIG welded onto the the side of the downpipe to catch the lower bell housing bolt. Kinda of a pain but it now is stabilized and nothing is hitting anything all the way back and out!

I had to have a local muffler shop double up two pipes and swedge them out to make the lip thicker on the end of the downpipe. According to a diesel buddy of mine this mimics the correct factory spec. making an exhaust leak or break at the turbine less likely.

I then TIG'ed the connection. The other photo is the bracket I modified that came off a toyota downpipe bracket. I MIG welded onto the the side of the downpipe to catch the lower bell housing bolt. Kinda of a pain but it now is stabilized and nothing is hitting anything all the way back and out!

The following 2 users liked this post by Morsel:

mknittle (12-11-2017),

thrashingcows (12-11-2017)

#13

Registered User

I agree. Good job!

#14

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,770

Received 1,637 Likes

on

1,112 Posts

#15

Registered User

Thread Starter

Thanks!

Right now ive got an injector pump leak I am researching. I am waiting on a few parts in order to pull the pump and fix this leak.

Right now ive got an injector pump leak I am researching. I am waiting on a few parts in order to pull the pump and fix this leak.