can't figure this low power issue out

#106

Registered User

I would try to repair the leaks -- what do you have to lose?

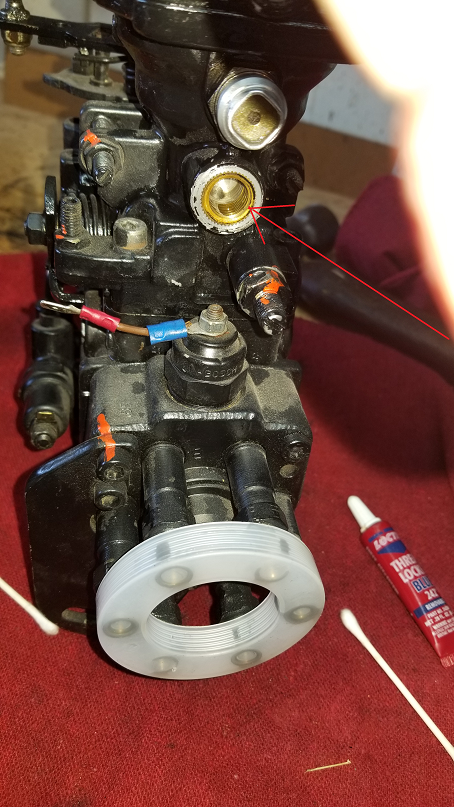

The fuel pin is probably leaking because of all the over-extension and fooling that has happened to it. It could have been pinched or rolled or otherwise damaged. It is also possible that you have scratched the pin itself (though that is unlikely as they are very hard) or the pin has some varnish stuck to it.

The locking bolt? Do you mean the one that locks the pump for removal? Perhaps you installed the wrong o-ring or installed it in the wrong place (probably not, but strange things sometimes happen). That is a pretty low-pressure area, it doesn't normally leak.

For the manual shut-off: I have had trouble identifying the correct o-ring, and of course everything has to be clean and scratch free and the flat washer has to be correct & in place.

Good luck with it -- you'll get it fixed in the end.

The fuel pin is probably leaking because of all the over-extension and fooling that has happened to it. It could have been pinched or rolled or otherwise damaged. It is also possible that you have scratched the pin itself (though that is unlikely as they are very hard) or the pin has some varnish stuck to it.

The locking bolt? Do you mean the one that locks the pump for removal? Perhaps you installed the wrong o-ring or installed it in the wrong place (probably not, but strange things sometimes happen). That is a pretty low-pressure area, it doesn't normally leak.

For the manual shut-off: I have had trouble identifying the correct o-ring, and of course everything has to be clean and scratch free and the flat washer has to be correct & in place.

Good luck with it -- you'll get it fixed in the end.

#107

I've got a problem.. no start

removed top of the ip to fix the slide pin leak. well fixed the leak but now truck won't start.

1. primed with the lever till no air bubbles came out of bleed screw.

2. filled ip through fill port on top

3. cracked all injectors and cranked. for a lot of cranks I wasn't even getting drips of fuel out of any of them!

after 100 cranks, I have been steadily getting fuel with air bubbles from injectors 2,3,4,5 injectors 1 and 6 are still dry, completely dry. also the injectors that are putting out fuel it isn't like it should be, it's coming out alright but it's not squirting on my hood like it normally would.

so my question is, how is it possible with this style of ip that I'm getting fuel from 4/6 injectors but not all? especially considering how much fuel I've gotten from the other 4? I'm at a complete loss here, no idea. hope someone can help because I've tried everything I can think of.

no it's not the throttle index, I've tried a few different ways but I've also removed my pump enough that I have got the throttle index spot on the 1st try the past 5 times I've pulled it.

shouldn't be my lift pump because it worked fine before this and it's priming the filter just fine. though the handle is floppy until the very bottom of the stroke. is this a sign that it may be bad? I've been cranking all day and pressure at the bottom is all I've been getting.

fuel screw all the way to the collar so it's not that either. (yes I still have my lock collar lol)

12v to the fss and it works.

can't think of anything else really. help!

removed top of the ip to fix the slide pin leak. well fixed the leak but now truck won't start.

1. primed with the lever till no air bubbles came out of bleed screw.

2. filled ip through fill port on top

3. cracked all injectors and cranked. for a lot of cranks I wasn't even getting drips of fuel out of any of them!

after 100 cranks, I have been steadily getting fuel with air bubbles from injectors 2,3,4,5 injectors 1 and 6 are still dry, completely dry. also the injectors that are putting out fuel it isn't like it should be, it's coming out alright but it's not squirting on my hood like it normally would.

so my question is, how is it possible with this style of ip that I'm getting fuel from 4/6 injectors but not all? especially considering how much fuel I've gotten from the other 4? I'm at a complete loss here, no idea. hope someone can help because I've tried everything I can think of.

no it's not the throttle index, I've tried a few different ways but I've also removed my pump enough that I have got the throttle index spot on the 1st try the past 5 times I've pulled it.

shouldn't be my lift pump because it worked fine before this and it's priming the filter just fine. though the handle is floppy until the very bottom of the stroke. is this a sign that it may be bad? I've been cranking all day and pressure at the bottom is all I've been getting.

fuel screw all the way to the collar so it's not that either. (yes I still have my lock collar lol)

12v to the fss and it works.

can't think of anything else really. help!

#108

Registered User

I've got a problem.. no start

removed top of the ip to fix the slide pin leak. well fixed the leak but now truck won't start.

1. primed with the lever till no air bubbles came out of bleed screw.

2. filled ip through fill port on top

3. cracked all injectors and cranked. for a lot of cranks I wasn't even getting drips of fuel out of any of them!

after 100 cranks, I have been steadily getting fuel with air bubbles from injectors 2,3,4,5 injectors 1 and 6 are still dry, completely dry. also the injectors that are putting out fuel it isn't like it should be, it's coming out alright but it's not squirting on my hood like it normally would.

so my question is, how is it possible with this style of ip that I'm getting fuel from 4/6 injectors but not all? especially considering how much fuel I've gotten from the other 4? I'm at a complete loss here, no idea. hope someone can help because I've tried everything I can think of.

no it's not the throttle index, I've tried a few different ways but I've also removed my pump enough that I have got the throttle index spot on the 1st try the past 5 times I've pulled it.

shouldn't be my lift pump because it worked fine before this and it's priming the filter just fine. though the handle is floppy until the very bottom of the stroke. is this a sign that it may be bad? I've been cranking all day and pressure at the bottom is all I've been getting.

fuel screw all the way to the collar so it's not that either. (yes I still have my lock collar lol)

12v to the fss and it works.

can't think of anything else really. help!

removed top of the ip to fix the slide pin leak. well fixed the leak but now truck won't start.

1. primed with the lever till no air bubbles came out of bleed screw.

2. filled ip through fill port on top

3. cracked all injectors and cranked. for a lot of cranks I wasn't even getting drips of fuel out of any of them!

after 100 cranks, I have been steadily getting fuel with air bubbles from injectors 2,3,4,5 injectors 1 and 6 are still dry, completely dry. also the injectors that are putting out fuel it isn't like it should be, it's coming out alright but it's not squirting on my hood like it normally would.

so my question is, how is it possible with this style of ip that I'm getting fuel from 4/6 injectors but not all? especially considering how much fuel I've gotten from the other 4? I'm at a complete loss here, no idea. hope someone can help because I've tried everything I can think of.

no it's not the throttle index, I've tried a few different ways but I've also removed my pump enough that I have got the throttle index spot on the 1st try the past 5 times I've pulled it.

shouldn't be my lift pump because it worked fine before this and it's priming the filter just fine. though the handle is floppy until the very bottom of the stroke. is this a sign that it may be bad? I've been cranking all day and pressure at the bottom is all I've been getting.

fuel screw all the way to the collar so it's not that either. (yes I still have my lock collar lol)

12v to the fss and it works.

can't think of anything else really. help!

Edwin

#109

Go back to the IP and loosen the return line banjo on the back of the pump. Then prime the heck out of it until there is absolutely no air in the pump. Then crack all of the injector lines at the injectors and crank until fuel with no air comes out of all of them then tighten them all down and start it up. If it runs rough then crack the injectors again on at a time and it will smooth out.

Edwin

Edwin

#111

yes I primed through that. I filled it through the fill port on top of the pump where the fuel feeds into the pump from the filter, primed the banjo in that pic and then cracked the fuel lines. still getting fuel out of 4/6 injectors but the first and last one are dry

#112

Banned

When you say you filled it through the fill port are you actually pouring fuel in the inlet banjo bolt? If so you are asking for trouble as you would be at great risk of entering contaminants into your injection pump with unfiltered diesel fuel. All of your priming of the fuel system should be done by pumping your lift pump on the side of the engine block.

It sounds to me like you don't have your pump bleed properly for it to start. If your getting a light amount of fuel from 2 thirds of your injection lines you do not have the air out of the supply side of your pump yet.

It sounds to me like you don't have your pump bleed properly for it to start. If your getting a light amount of fuel from 2 thirds of your injection lines you do not have the air out of the supply side of your pump yet.

#113

When you say you filled it through the fill port are you actually pouring fuel in the inlet banjo bolt? If so you are asking for trouble as you would be at great risk of entering contaminants into your injection pump with unfiltered diesel fuel. All of your priming of the fuel system should be done by pumping your lift pump on the side of the engine block.

It sounds to me like you don't have your pump bleed properly for it to start. If your getting a light amount of fuel from 2 thirds of your injection lines you do not have the air out of the supply side of your pump yet.

It sounds to me like you don't have your pump bleed properly for it to start. If your getting a light amount of fuel from 2 thirds of your injection lines you do not have the air out of the supply side of your pump yet.

#114

just tried ether still no go. though it did crank a lot faster than normal lol. smells like burnt ether. too bad it still didn't start though and still no fuel from 1 or 6 I'll keep cranking

#115

Registered User

Here's the procedure I use and it assumes your pump and filter are dry. all lines are connected.

Loosen the bleeder on the banjo bolt at the filter output. Then pump the primer until fuel shoots out of the bleeder. Tighten the bleeder down.

Loosen the banjo bolt at the back of the VE pump which is the return line. Pump the primer until fuel comes steadily out of the banjo. then tighten the banjo.

The injector lines at all six injectors should be slightly cracked. Crank the engine until fuel is coming out all six injector lines. then tighten them all down.

Start the engine. If it runs rough and doesn't smooth out then you can carefully loosen the lines one at a time while the engine is running to bleed any residual air out.

Always wear safety goggles and gloves when cracking the injector lines because the high pressure fuel can cut you.

#116

Registered User

Using ether with grid heaters is dangerous. Don't do it.

Here's the procedure I use and it assumes your pump and filter are dry. all lines are connected.

Loosen the bleeder on the banjo bolt at the filter output. Then pump the primer until fuel shoots out of the bleeder. Tighten the bleeder down.

Loosen the banjo bolt at the back of the VE pump which is the return line. Pump the primer until fuel comes steadily out of the banjo. then tighten the banjo.

The injector lines at all six injectors should be slightly cracked. Crank the engine until fuel is coming out all six injector lines. then tighten them all down.

Start the engine. If it runs rough and doesn't smooth out then you can carefully loosen the lines one at a time while the engine is running to bleed any residual air out.

Always wear safety goggles and gloves when cracking the injector lines because the high pressure fuel can cut you.

Here's the procedure I use and it assumes your pump and filter are dry. all lines are connected.

Loosen the bleeder on the banjo bolt at the filter output. Then pump the primer until fuel shoots out of the bleeder. Tighten the bleeder down.

Loosen the banjo bolt at the back of the VE pump which is the return line. Pump the primer until fuel comes steadily out of the banjo. then tighten the banjo.

The injector lines at all six injectors should be slightly cracked. Crank the engine until fuel is coming out all six injector lines. then tighten them all down.

Start the engine. If it runs rough and doesn't smooth out then you can carefully loosen the lines one at a time while the engine is running to bleed any residual air out.

Always wear safety goggles and gloves when cracking the injector lines because the high pressure fuel can cut you.

#117

Using ether with grid heaters is dangerous. Don't do it.

Here's the procedure I use and it assumes your pump and filter are dry. all lines are connected.

Loosen the bleeder on the banjo bolt at the filter output. Then pump the primer until fuel shoots out of the bleeder. Tighten the bleeder down.

Loosen the banjo bolt at the back of the VE pump which is the return line. Pump the primer until fuel comes steadily out of the banjo. then tighten the banjo.

The injector lines at all six injectors should be slightly cracked. Crank the engine until fuel is coming out all six injector lines. then tighten them all down.

Start the engine. If it runs rough and doesn't smooth out then you can carefully loosen the lines one at a time while the engine is running to bleed any residual air out.

Always wear safety goggles and gloves when cracking the injector lines because the high pressure fuel can cut you.

Here's the procedure I use and it assumes your pump and filter are dry. all lines are connected.

Loosen the bleeder on the banjo bolt at the filter output. Then pump the primer until fuel shoots out of the bleeder. Tighten the bleeder down.

Loosen the banjo bolt at the back of the VE pump which is the return line. Pump the primer until fuel comes steadily out of the banjo. then tighten the banjo.

The injector lines at all six injectors should be slightly cracked. Crank the engine until fuel is coming out all six injector lines. then tighten them all down.

Start the engine. If it runs rough and doesn't smooth out then you can carefully loosen the lines one at a time while the engine is running to bleed any residual air out.

Always wear safety goggles and gloves when cracking the injector lines because the high pressure fuel can cut you.

got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

#118

Registered User

what's a grid heater?  got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

got rid of it a long time ago. anyways this is exactly how I do it. still only getting dribbles from the injectors with an occasional air bubble now. no bubbles coming from filter bleeder bolt or return line banjo on ip. I have started this exact procedure from step 1 countless times now not much changes. I have also tried it with throttle to the floor just in case my indexing is off but I've also moved the indexing around too nothing... does the tps have to be connected for the truck to start? might take throttle assembly off if not and play with the throttle indexing while trying to start it and see if somehow that helps vs the gas pedal. idk I'm just out of ideas.

If your throttle index is off that could possibly be your problem. It could be set lower than idle and completely shutting off fuel. Could the governor spring have slipped off?

I don't know what the procedure is for getting it indexed properly so hopefully somebody with more knowledge will chime in here.

#119

I don't think the TPS being disconnected would be a problem but then I don't have one so can't say for sure. I would think that would only affect the transmission.

If your throttle index is off that could possibly be your problem. It could be set lower than idle and completely shutting off fuel. Could the governor spring have slipped off?

I don't know what the procedure is for getting it indexed properly so hopefully somebody with more knowledge will chime in here.

If your throttle index is off that could possibly be your problem. It could be set lower than idle and completely shutting off fuel. Could the governor spring have slipped off?

I don't know what the procedure is for getting it indexed properly so hopefully somebody with more knowledge will chime in here.

im in trouble if my spring slipped off lol! nah those things are a PITA to get off with how curved in the tips (connecting parts) are, plus the throttle shaft springs back like it should so thats not it. the index mark lines up with the second hash mark on the linkage, mines set right according to that right now, ive tried it up to 2 teeth further (opening the throttle) and 2 teeth the other way (closing the throttle).

even IF the indexing was off (to low) would it still shut fuel off if i gave it wide open throttle while cranking? i would think it would just die at idle and be low on power seeing how it works but maybe im wrong, maybe i need to try 3 teeth over and put it closer to the 3rd mark idk worth a try

#120

Registered User

Sometimes you just have to back off of a problem and think about it for a while. Put the charger on your battery and go in the house and have some coffee or take a nap. Wait for somebody else to chime in here with maybe a solution or further insight.

Sorry you're having so many problems.

Edwin

Sorry you're having so many problems.

Edwin