BC's Transmission Overhaul (updated as it occurs)

#1

1st Generation Admin

Thread Starter

Well, I guess it's on . . . .

I've pretty much exhausted any excuse for not getting to it.

Right off, I'm thinking that instead of raising the truck off the ground level, I might come out ahead aggravation wise if I have the rear of the truck higher than the front. The idea is: After clearing all the stuff out of the way, I'll lower the trans and butt of the CTD so as to remove the trans. My point is with the truck set level, the trans/engine will be angled relative to the ground. While the trans-jack has the ability to accommodate said angle(s), I'll have no problem removing the trans, . . . . but it would be something of a pain to get it back together considering the angle.

With having the truck at an angle (adjusted as needed on disassembly), reinstalling the trans will mean simply having the trans and jack set level, raise the load, and push it straight to the CTD.

Make sense?

So what's a good, economical, and safe means of raising the truck? I need to measure things but the bottom line is I need to get it high enough to be able to clear the height of the trans going out, and back under the truck - - ideally while the trans is mounted on the jack.

I'm thinking of using some 6" x 6" x 12" cribbing set so there's two pieces on the ground, with a third crossing those with the truck tire sitting on that. I don't want to use the typical safety stand as they would be extended to their max and ultimately might allow the truck to rock a bit should I decide on shoving something. There's better ways of getting thin.

Wha'chawl reckon?

I've pretty much exhausted any excuse for not getting to it.

Right off, I'm thinking that instead of raising the truck off the ground level, I might come out ahead aggravation wise if I have the rear of the truck higher than the front. The idea is: After clearing all the stuff out of the way, I'll lower the trans and butt of the CTD so as to remove the trans. My point is with the truck set level, the trans/engine will be angled relative to the ground. While the trans-jack has the ability to accommodate said angle(s), I'll have no problem removing the trans, . . . . but it would be something of a pain to get it back together considering the angle.

With having the truck at an angle (adjusted as needed on disassembly), reinstalling the trans will mean simply having the trans and jack set level, raise the load, and push it straight to the CTD.

Make sense?

So what's a good, economical, and safe means of raising the truck? I need to measure things but the bottom line is I need to get it high enough to be able to clear the height of the trans going out, and back under the truck - - ideally while the trans is mounted on the jack.

I'm thinking of using some 6" x 6" x 12" cribbing set so there's two pieces on the ground, with a third crossing those with the truck tire sitting on that. I don't want to use the typical safety stand as they would be extended to their max and ultimately might allow the truck to rock a bit should I decide on shoving something. There's better ways of getting thin.

Wha'chawl reckon?

#3

Registered User

It took 170psi of air to lift the front of the truck with that jack, I had to raise it more to get the trans out on the jack. I think I raised it more than a foot.

I've done it with the np205 attached, that thing is heavy, all it wants to do is drag the trans off the jack if you don't strap it down right.

I would use 2 hydraulic jacks and a bunch of cribbing, you're probably going to have to jack it up 2 or 3 time and set cribbing under the wheels and then crib the jacks up. The angle won't really be a problem, the trans jack will accommodate that. The first time is always a challenge, but after you done a few of them you get better that it. The smoother and leveler the surface you're working on the easier it will be.

#4

1st Generation Admin

Thread Starter

Thanks for the tips Mike.

. . . I see those cinder blocks under the front tires there.

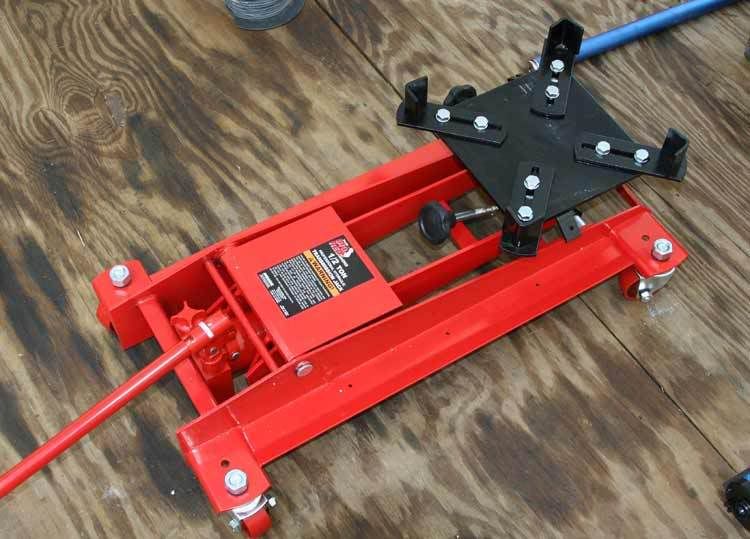

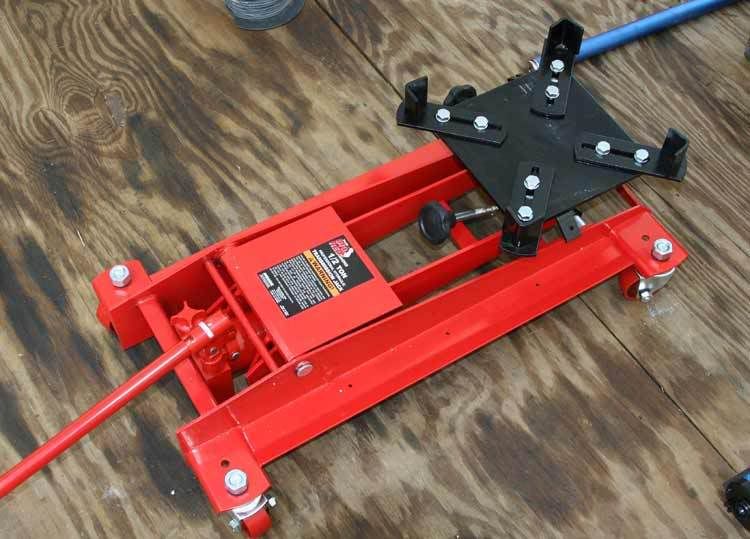

That jack up front there looks a bit wimpy don't you think? The trans jack a bit flimsy. Where are you working, a locomotive foundry?

Where are you working, a locomotive foundry?

Got the SFI flexplate, torque converter, and the start of the internal components on order. Still gotta finish sorting out the balance of the innards. Gonna wait till I get it torn down before proceeding from there.

I need to go out and cut up the cribbing.

. . . I see those cinder blocks under the front tires there.

That jack up front there looks a bit wimpy don't you think? The trans jack a bit flimsy.

Where are you working, a locomotive foundry?

Where are you working, a locomotive foundry?Got the SFI flexplate, torque converter, and the start of the internal components on order. Still gotta finish sorting out the balance of the innards. Gonna wait till I get it torn down before proceeding from there.

I need to go out and cut up the cribbing.

#5

Registered User

Yes, yes those are cinder blocks. You can't really see it, but there isn't alot of weight on the front end, plus there are jack stands under there too, plus the jack has positive locks.

The tag on the trans jack says 1000lb capacity, I think they underrated it slightly. I was working outside our shop at that time, now I work in the shop on a concrete floor or up on the lift. I borrowed a tall trans jack the last time, what a difference, started at 7pm and had the new trans and transfer case in by 1:30am, this included switching parts and a tear down on the old unit to determine the failure.

What else you going to order? I'll PM you my number in case you want to talk to me, I just got done doing one again.

What else you going to order? I'll PM you my number in case you want to talk to me, I just got done doing one again.

#6

1st Generation Admin

Thread Starter

Well, I've receaved the

- SunCoast torque converter,

For the intermediate ~

- A 2 3/16 inch Rigid Red band,

- A billet band strut and anchor,

- 6 Alto Red frictions & 6 Kolene steels,

- Updated lip seals and Teflon rings,

- Piston, pressure plate and snap ring.

Still gotta get more internal stuff.

Got the 6"x6"x12" cribbing cut up.

I'm on-call for work and don't dare start anything.

- SunCoast torque converter,

For the intermediate ~

- A 2 3/16 inch Rigid Red band,

- A billet band strut and anchor,

- 6 Alto Red frictions & 6 Kolene steels,

- Updated lip seals and Teflon rings,

- Piston, pressure plate and snap ring.

Still gotta get more internal stuff.

Got the 6"x6"x12" cribbing cut up.

I'm on-call for work and don't dare start anything.

#7

1st Generation Admin

Thread Starter

Well, I finally got to it.

Thus far I've got the exhaust plumbing, front and rear drive-shafts, skid-plate, and transfer-case out.

- > Those exhaust band-clamps just paid for themselves BIG-TIME!

? --> The drive-shafts are still sporting the OEM universal joints with 224,000 miles. Ya reckon I ought to go ahead and replace the rear shaft's joints as a predictive maintenance thing? I've kept them lubricated through the years. Any particular part numbers to watch out for?

? --> What about that center bearing? As removed I don't know that it has a problem however I did notice the resilient rubber ring that it nests in is deteriorating.

I think I want to replace the transfer case's rear output shaft seal. It looks as though I'll need to remove that yoke to get to it. That ought'a be fun.

Still gotta remove the starter, transmission fluid lines, shifter/kick-down cables, and the electrics before finally dropping the transmission itself.

EDIT ~ I did mark both drive-shaft's yokes relative to those on the transfer case and differentials before removing

So far so good.

Thus far I've got the exhaust plumbing, front and rear drive-shafts, skid-plate, and transfer-case out.

- > Those exhaust band-clamps just paid for themselves BIG-TIME!

? --> The drive-shafts are still sporting the OEM universal joints with 224,000 miles. Ya reckon I ought to go ahead and replace the rear shaft's joints as a predictive maintenance thing? I've kept them lubricated through the years. Any particular part numbers to watch out for?

? --> What about that center bearing? As removed I don't know that it has a problem however I did notice the resilient rubber ring that it nests in is deteriorating.

I think I want to replace the transfer case's rear output shaft seal. It looks as though I'll need to remove that yoke to get to it. That ought'a be fun.

Still gotta remove the starter, transmission fluid lines, shifter/kick-down cables, and the electrics before finally dropping the transmission itself.

EDIT ~ I did mark both drive-shaft's yokes relative to those on the transfer case and differentials before removing

So far so good.

Trending Topics

#9

1st Generation Admin

Thread Starter

? --> Should I start spraying Monkey-Spunk on those transmission fluid heat exchanger fittings now? Uggg. Livesay Law insists they absolutely will NOT fall right off. Having to replace the exchanger because I wrung the stupid fittings off is NOT on the agenda.

#10

Registered User

? --> The drive-shafts are still sporting the OEM universal joints with 224,000 miles. Ya reckon I ought to go ahead and replace the rear shaft's joints as a predictive maintenance thing? I've kept them lubricated through the years. Any particular part numbers to watch out for?

I would, even if you ring the tubing off, the fittings that go into the heat exchanger are tapered pipe thread. So if the worst does happen all hope is not lost.

#11

Registered User

If yer going to replace the u-joints, IMO get genuine Spicers, the stuff from the local parts store are OK but if you compare them next to some spicer`s you`ll see what I mean. Glad you got the ball rolling, best of luck with it, it`s a pretty big job.

#12

Registered User

? --> The drive-shafts are still sporting the OEM universal joints with 224,000 miles. Ya reckon I ought to go ahead and replace the rear shaft's joints as a predictive maintenance thing? I've kept them lubricated through the years. Any particular part numbers to watch out for?

Go with Spicers; for the rear driveshaft (1410 series joints) the non-greasable are 5-801X and the greasable are 5-160X.

#13

1st Generation Admin

Thread Starter

Ace, Mike, Tom, Chris, All of ya, Thanks for the feedback.

I'll take the rear drive-shaft to Loop Road Auto Parts in Garner and have my friends there install new Spicer U-Joints and a center bearing assembly. I'm thinking the OEM greasable models have served me well, 5-160X, no sense in re-engineering that. They've a full service machine shop I've a long history with.

Got to a late start tonight and was only able to remove the transfer case shifter assembly and the torque converter/flex-plate bolts. Drained the trans.

I 'spect the actual trans will come out tomorrow. Then it's pressure wash everything.

The box of stuff is suppose to show up Monday.

BTW, In reviewing the FSM . . . . again, I read a section referring to the transfer case and the speedometer adapter. Something about indexing or something, can't remember now.

I'll take the rear drive-shaft to Loop Road Auto Parts in Garner and have my friends there install new Spicer U-Joints and a center bearing assembly. I'm thinking the OEM greasable models have served me well, 5-160X, no sense in re-engineering that. They've a full service machine shop I've a long history with.

Got to a late start tonight and was only able to remove the transfer case shifter assembly and the torque converter/flex-plate bolts. Drained the trans.

I 'spect the actual trans will come out tomorrow. Then it's pressure wash everything.

The box of stuff is suppose to show up Monday.

BTW, In reviewing the FSM . . . . again, I read a section referring to the transfer case and the speedometer adapter. Something about indexing or something, can't remember now.

#14

1st Generation Admin

Thread Starter

I sorta drug around today, it was HOT! (and gonna get worse this coming week).

Finally got to removing the balance of the wiring harness, the shift linkage/torque lever assembly, kick-down cable, rear cross-member, and this mess ~

Your basic A518 3 speed automatic with overdrive (AKA 46RH)

Tomorrow (Sunday) will be wash day.

? --> The danged dip-stick tube would NOT come out of the case. It moves around easily. Doesn't it just plug into place and seals with an O-ring?

Finally got to removing the balance of the wiring harness, the shift linkage/torque lever assembly, kick-down cable, rear cross-member, and this mess ~

Your basic A518 3 speed automatic with overdrive (AKA 46RH)

Tomorrow (Sunday) will be wash day.

? --> The danged dip-stick tube would NOT come out of the case. It moves around easily. Doesn't it just plug into place and seals with an O-ring?

#15

1st Generation Admin

Thread Starter

Again, it was HOT today!

Got all the drive-line components washed. I've placed all the nuts-n-bolts back in their respective holes so as not to be lost or confused.

Then climbed under the heap to clean it's underside.

Then I had to turn the pressure-washer on me.

Got all the drive-line components washed. I've placed all the nuts-n-bolts back in their respective holes so as not to be lost or confused.

Then climbed under the heap to clean it's underside.

Then I had to turn the pressure-washer on me.