Chas'in Leaks . . .

#48

1st Generation Admin

Thread Starter

Oddly, when I walk past the truck lately, I hear in the background those two notes of the theme song from "Jaws!".

Well I was tired yesterday after work so I came home a little early (thanks boss) and took a nap. Woke up about 8:00 and said "Shoot! Can't sleep now" and went to piddling with the truck. One thing led to another and . . . . .

Woke up about 8:00 and said "Shoot! Can't sleep now" and went to piddling with the truck. One thing led to another and . . . . .

. . .. it lives.

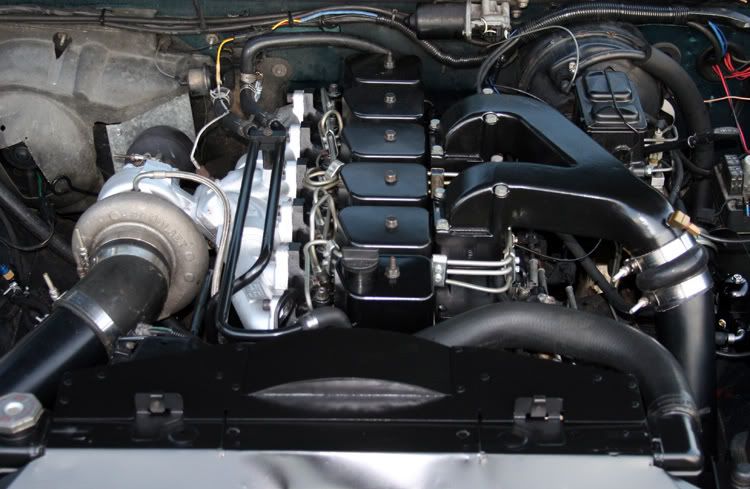

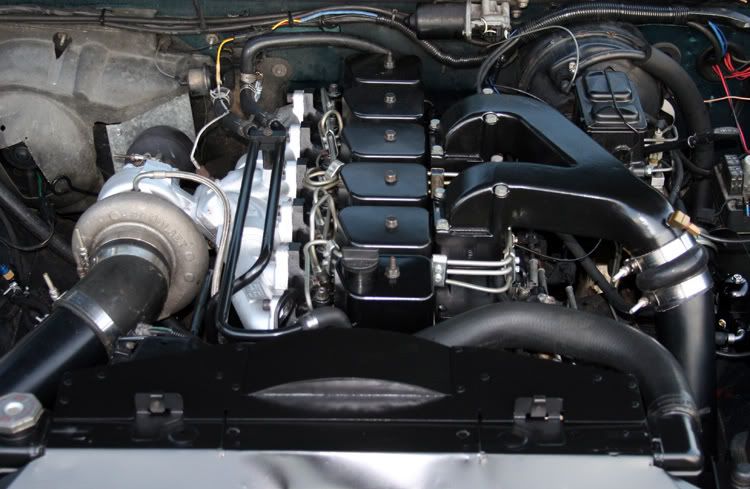

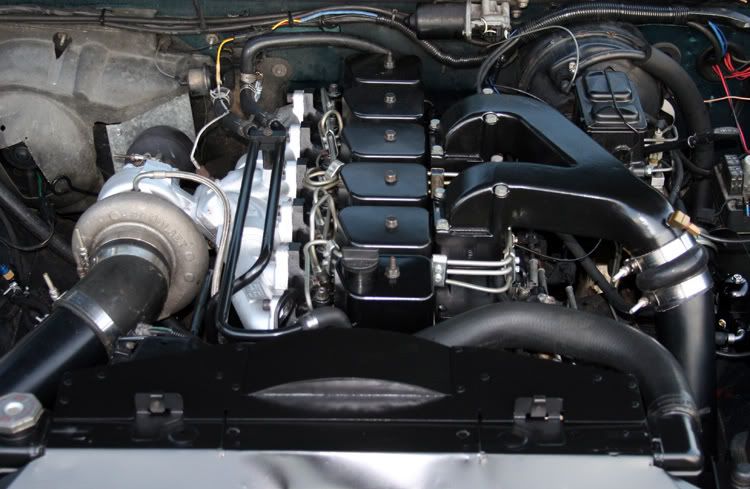

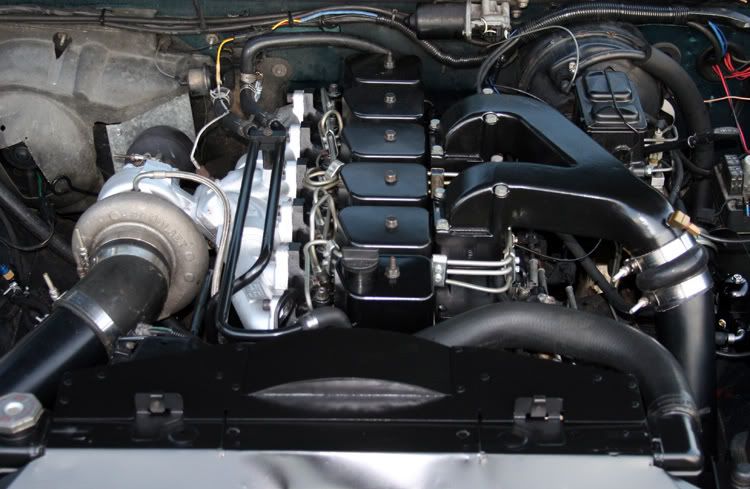

Here she warms up for the first hot torque of the head studs.

I found that removing the engine cooling fan altogether helped the engine come on up to temp with just idling. I let it go all the way to the second mark on the stupid-gauge and have the coolant thermostat open fully. Running the vent on hot/high pretty-much kept the engine on the high side of half-way on the stupid-gauge. I let it percolate for about 15 minutes.

When me and the wrench last laid hands on the studs, they were at 125ft/lbs torque cold. With the engine hot, I had to pull about 50% of the studs up to 100ft/lbs. Once there, all less the studs holding the valve rocker pedestals had to pulled to 125ft/lbs torque.

Since the head's all new and oily, I'm running a mild cooling system flush to get out the slick. Flush it a couple of times and I have got to go to the landfill . . . . . so says the wife!

Oh. By the way . . . .. No Leaks.

Well I was tired yesterday after work so I came home a little early (thanks boss) and took a nap.

Woke up about 8:00 and said "Shoot! Can't sleep now" and went to piddling with the truck. One thing led to another and . . . . .

Woke up about 8:00 and said "Shoot! Can't sleep now" and went to piddling with the truck. One thing led to another and . . . . . . . .. it lives.

Here she warms up for the first hot torque of the head studs.

I found that removing the engine cooling fan altogether helped the engine come on up to temp with just idling. I let it go all the way to the second mark on the stupid-gauge and have the coolant thermostat open fully. Running the vent on hot/high pretty-much kept the engine on the high side of half-way on the stupid-gauge. I let it percolate for about 15 minutes.

When me and the wrench last laid hands on the studs, they were at 125ft/lbs torque cold. With the engine hot, I had to pull about 50% of the studs up to 100ft/lbs. Once there, all less the studs holding the valve rocker pedestals had to pulled to 125ft/lbs torque.

Since the head's all new and oily, I'm running a mild cooling system flush to get out the slick. Flush it a couple of times and I have got to go to the landfill . . . . . so says the wife!

Oh. By the way . . . .. No Leaks.

#50

1st Generation Admin

Thread Starter

Thanks folks.

I've pretty-much finished buttoning things up. I had to grind a little off the internal webbing of the valve covers so they'd clear the stud nuts. While I had things apart, I went ahead and repainted the fan and radiator shroud/plate stuff.

I've completed the cooling system cleaning and flushing. I've still got to do a couple more hot re-torques before really getting on it. I managed to get two full heat-up and full cool-down cycles driving into town today so far. I'm hoping to get one more in tonight. At this point, I'm running with the AFC boost reference tube completely removed. With that, I still have to watch it to keep from going above 10psig boost.

This should be interesting from the "What's porting a CTD head good for?" point of view as I've not changed a thing regarding the engine's performance trim and tuning.

This driving it easy for a bit is killing me . .. How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

I've pretty-much finished buttoning things up. I had to grind a little off the internal webbing of the valve covers so they'd clear the stud nuts. While I had things apart, I went ahead and repainted the fan and radiator shroud/plate stuff.

I've completed the cooling system cleaning and flushing. I've still got to do a couple more hot re-torques before really getting on it. I managed to get two full heat-up and full cool-down cycles driving into town today so far. I'm hoping to get one more in tonight. At this point, I'm running with the AFC boost reference tube completely removed. With that, I still have to watch it to keep from going above 10psig boost.

This should be interesting from the "What's porting a CTD head good for?" point of view as I've not changed a thing regarding the engine's performance trim and tuning.

This driving it easy for a bit is killing me . ..

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

#54

Registered User

Thanks folks.

I've pretty-much finished buttoning things up. I had to grind a little off the internal webbing of the valve covers so they'd clear the stud nuts. While I had things apart, I went ahead and repainted the fan and radiator shroud/plate stuff.

I've completed the cooling system cleaning and flushing. I've still got to do a couple more hot re-torques before really getting on it. I managed to get two full heat-up and full cool-down cycles driving into town today so far. I'm hoping to get one more in tonight. At this point, I'm running with the AFC boost reference tube completely removed. With that, I still have to watch it to keep from going above 10psig boost.

This should be interesting from the "What's porting a CTD head good for?" point of view as I've not changed a thing regarding the engine's performance trim and tuning.

This driving it easy for a bit is killing me . .. How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

I've pretty-much finished buttoning things up. I had to grind a little off the internal webbing of the valve covers so they'd clear the stud nuts. While I had things apart, I went ahead and repainted the fan and radiator shroud/plate stuff.

I've completed the cooling system cleaning and flushing. I've still got to do a couple more hot re-torques before really getting on it. I managed to get two full heat-up and full cool-down cycles driving into town today so far. I'm hoping to get one more in tonight. At this point, I'm running with the AFC boost reference tube completely removed. With that, I still have to watch it to keep from going above 10psig boost.

This should be interesting from the "What's porting a CTD head good for?" point of view as I've not changed a thing regarding the engine's performance trim and tuning.

This driving it easy for a bit is killing me . ..

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

How many hot re-torques do those with O-rings and studs do before things are typically termed "Set"?

David,

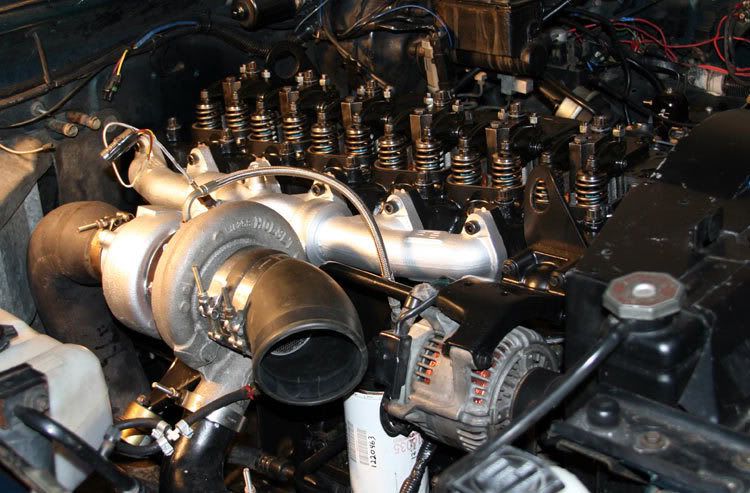

Awsome looking, where did you get the twin ram? How much?

#55

1st Generation Admin

Thread Starter

Thanks folks.

Phil I got the TwinRam from Scheid Diesel a couple of years ago. They were kind enough to bend up some injector lines for it on a mock-up block out back.

Tonight I went about doing the second hot re-torque of the head studs. After backing them off maybe a 16th of a turn, I was able to pull them all back to 125ft/lbs in perhaps an 8th to 1/4 turn. As I worked in the customary spiral pattern in loosening, and re-tightening, I got to the rocker arm pedestal of cylinder five and . . ..

. . .. . . an off tone "thump" was felt in the head of the torque wrench and it's pressure released!

OH! MY! GOD!

Folks, had I not hit the head before starting this tonight, I'm sure I would have streaked my draws!!!

I almost came to tears!!

I said "Shaw!" (cept it wasn't that nice ) and went to back-out what would come out. Something "popped" again as I went to back it out and the stupid ratchet fell over!

) and went to back-out what would come out. Something "popped" again as I went to back it out and the stupid ratchet fell over!

The dag'gum 1/2" drive to 3/8" drive adapter I was using had failed!!

CRAP and WHEW!!

So I went out looking a durn replacement adapter and finally got back to realize the engine had cooled enough that I needed to do it all over. Put it back together, heat it back up, tear it down, and torque the mess again.

Put it back together, heat it back up, tear it down, and torque the mess again.

Then adjust the valves while the block is still hot. .008" intake, and .018" exhaust.

With the exception of breaking cheap tools and having subsequent cheat pains, I'm getting pretty good at this mess. A couple more days of full heating/cooling cycles, and striking it one more time with the torque wrench ought to have it about right.

A couple more days of full heating/cooling cycles, and striking it one more time with the torque wrench ought to have it about right.

Driving it around tonight afterward, I put a little more heat to it as it were. I still don't have the AFC boost reference tube hooked up so I'm still pretty light on the squirter's yet it'll jump to at least 30psig boost without much effort. At this point, I'm gently bringing it up to about 30psig for say 30 seconds and back down. Within a moment, one can feel the cab heater blowing much warmer air (heat of the fuel coming around / thermal peak).

It appears I can do 60mph with about 600*F EGT at less than 5psig boost.

One more time, and this boy's off to the track.

Phil I got the TwinRam from Scheid Diesel a couple of years ago. They were kind enough to bend up some injector lines for it on a mock-up block out back.

Tonight I went about doing the second hot re-torque of the head studs. After backing them off maybe a 16th of a turn, I was able to pull them all back to 125ft/lbs in perhaps an 8th to 1/4 turn. As I worked in the customary spiral pattern in loosening, and re-tightening, I got to the rocker arm pedestal of cylinder five and . . ..

. . .. . . an off tone "thump" was felt in the head of the torque wrench and it's pressure released!

OH! MY! GOD!

Folks, had I not hit the head before starting this tonight, I'm sure I would have streaked my draws!!!

I almost came to tears!!

I said "Shaw!" (cept it wasn't that nice

) and went to back-out what would come out. Something "popped" again as I went to back it out and the stupid ratchet fell over!

) and went to back-out what would come out. Something "popped" again as I went to back it out and the stupid ratchet fell over!The dag'gum 1/2" drive to 3/8" drive adapter I was using had failed!!

CRAP and WHEW!!

So I went out looking a durn replacement adapter and finally got back to realize the engine had cooled enough that I needed to do it all over.

Put it back together, heat it back up, tear it down, and torque the mess again.

Put it back together, heat it back up, tear it down, and torque the mess again.Then adjust the valves while the block is still hot. .008" intake, and .018" exhaust.

With the exception of breaking cheap tools and having subsequent cheat pains, I'm getting pretty good at this mess.

A couple more days of full heating/cooling cycles, and striking it one more time with the torque wrench ought to have it about right.

A couple more days of full heating/cooling cycles, and striking it one more time with the torque wrench ought to have it about right. Driving it around tonight afterward, I put a little more heat to it as it were. I still don't have the AFC boost reference tube hooked up so I'm still pretty light on the squirter's yet it'll jump to at least 30psig boost without much effort. At this point, I'm gently bringing it up to about 30psig for say 30 seconds and back down. Within a moment, one can feel the cab heater blowing much warmer air (heat of the fuel coming around / thermal peak).

It appears I can do 60mph with about 600*F EGT at less than 5psig boost.

One more time, and this boy's off to the track.

#56

Registered User

Join Date: Feb 2006

Location: West Jordan, UT

Posts: 326

Likes: 0

Received 0 Likes

on

0 Posts

Dang - gotta hate that twisty off the 3/8's thingy  - been there done that and not neccessarily always the cheap tools - though the cheap always go first.

- been there done that and not neccessarily always the cheap tools - though the cheap always go first.

Nice job. Looks like it means business.

- been there done that and not neccessarily always the cheap tools - though the cheap always go first.

- been there done that and not neccessarily always the cheap tools - though the cheap always go first.Nice job. Looks like it means business.

#58

Registered User

Can you get a 1/2" drive socket to do the job? It will give a better torque reading. That adapter is going to deflect.(obviouslt it did....alot!).

Just my 2$.

Very nice work! Should be fun with the newfound airflow.

Just my 2$.

Very nice work! Should be fun with the newfound airflow.

#59

1st Generation Admin

Thread Starter

I must be getting older as THAT thought came to me as I was standing there looking the replacement adapter. Naturally I couldn't tell myself what size socket.

(I was still reeling from the thought of a broken stud I suppose).

(I was still reeling from the thought of a broken stud I suppose).

For a while now I think these studs are the highest torqued I've messed with. As such the majority of my socket tools are 3/8ths.

I've got a 1" drive socket set and no ratchet for it. For the rear-end yoke nut, I grab the correct socket, and my big pipe wrench.

(I was still reeling from the thought of a broken stud I suppose).

(I was still reeling from the thought of a broken stud I suppose).For a while now I think these studs are the highest torqued I've messed with. As such the majority of my socket tools are 3/8ths.

I've got a 1" drive socket set and no ratchet for it. For the rear-end yoke nut, I grab the correct socket, and my big pipe wrench.

#60

1st Generation Admin

Thread Starter

Well . . . . . . . the original topic of this thread was . . . ..

- To find and fix some antifreeze leaks. Check.

- Predictive maintenance replacement of the engine oil cooler. Check.

- To cut a hole in the back of the block with a torch and plug it with an expensive piece of iron. Check.

- Replace the head with one that's had "Hands layed on it". Check.

- Better ensure combustion pressure containment via 12mm studs, O-rings, and drilling the exhaust housing's waste-gate/volute. Check.

- Squirt paint at it. Check.

Runs real nice.

Anyhoot, I've not been expecting any jaw-dropping performance improvements as the gist of what's been changed performance wise is the head flows a little better than stock. For that very reason, nothing's been changed mod/tuning wise so that I might be better able to compare things. My observations are just that.

It seems the boost is a little slower in coming up that last eight or so psig on it's way to a waste-gated 38psig max. It's my understanding a more accurate way to interpret "Boost" is to look at it as a measure of resistance to airflow through the engine. All else being the same, increasing a given engine's volumetric efficiency will present as a lower "Boost" figure.

OK, cool.

General around town driving seems to present as a little cooler EGT-wise though I've not really been studying on that.

Making a couple or six passes down the local 1/8" mile track presents with the following . . .

If one were to consider having last years all time best 1/8th time as being tonight's average (six passes, +/- approx .06 sec) as being a general improvement performance wise, then yes . . . . . .

EXCELLENT!

A little slow off the line . ..

Oh, new track rules mandate me wearing a helmet if I'm gonna continue running quicker than 9.0.

- To find and fix some antifreeze leaks. Check.

- Predictive maintenance replacement of the engine oil cooler. Check.

- To cut a hole in the back of the block with a torch and plug it with an expensive piece of iron. Check.

- Replace the head with one that's had "Hands layed on it". Check.

- Better ensure combustion pressure containment via 12mm studs, O-rings, and drilling the exhaust housing's waste-gate/volute. Check.

- Squirt paint at it. Check.

Runs real nice.

Anyhoot, I've not been expecting any jaw-dropping performance improvements as the gist of what's been changed performance wise is the head flows a little better than stock. For that very reason, nothing's been changed mod/tuning wise so that I might be better able to compare things. My observations are just that.

It seems the boost is a little slower in coming up that last eight or so psig on it's way to a waste-gated 38psig max. It's my understanding a more accurate way to interpret "Boost" is to look at it as a measure of resistance to airflow through the engine. All else being the same, increasing a given engine's volumetric efficiency will present as a lower "Boost" figure.

OK, cool.

General around town driving seems to present as a little cooler EGT-wise though I've not really been studying on that.

Making a couple or six passes down the local 1/8" mile track presents with the following . . .

If one were to consider having last years all time best 1/8th time as being tonight's average (six passes, +/- approx .06 sec) as being a general improvement performance wise, then yes . . . . . .

EXCELLENT!

A little slow off the line . ..

Oh, new track rules mandate me wearing a helmet if I'm gonna continue running quicker than 9.0.