My lift pump/ CP3 feed solution

#62

"Yes, the engine mounted pumps are vane type pumps.

What are the in-tank pumps?"

I dunno.

"One more thing people have to consider when installing fuel filters in line some where is cold temps. They will plug without some type of heat system or alot of blended fuel and or anti-gel additive."

Shouldn't make much difference to the pump except that cold fuel is hard to push through the filter(s).

"the duramax uses a 1/2 inch fuel line and still sees presure drops on wot with a good lift pump installed, most heavy modded cummins i have talked to replace the 3/8 with a larger line, we found any higher than 40 psi liftpump pressure to the cp3 has caused problems to the fuel filter canister"

There is no need to replace the 3/8" line. The problem is that you guys are running a pressure relief valve and returning the supply to the tank before it gets to the filter. It would be much better to push 100% of the Walbro flow through the filter to the CP3 and leave the CP3 take as much or little as it needs. I don't understand why people find this so hard to understand.

The filter backpressure when the filter is clean is only a few PSI for the full Walbro 392 flow, which is much, much more than the CP3 needs, even running 600 HP.

"can that 392 pump be regulated down in pressure and still maintain decent flow?"

There is no need to regulate the pressure down. Just install the bypass and let the CP3 take as much or as little as it needs.

What are the in-tank pumps?"

I dunno.

"One more thing people have to consider when installing fuel filters in line some where is cold temps. They will plug without some type of heat system or alot of blended fuel and or anti-gel additive."

Shouldn't make much difference to the pump except that cold fuel is hard to push through the filter(s).

"the duramax uses a 1/2 inch fuel line and still sees presure drops on wot with a good lift pump installed, most heavy modded cummins i have talked to replace the 3/8 with a larger line, we found any higher than 40 psi liftpump pressure to the cp3 has caused problems to the fuel filter canister"

There is no need to replace the 3/8" line. The problem is that you guys are running a pressure relief valve and returning the supply to the tank before it gets to the filter. It would be much better to push 100% of the Walbro flow through the filter to the CP3 and leave the CP3 take as much or little as it needs. I don't understand why people find this so hard to understand.

The filter backpressure when the filter is clean is only a few PSI for the full Walbro 392 flow, which is much, much more than the CP3 needs, even running 600 HP.

"can that 392 pump be regulated down in pressure and still maintain decent flow?"

There is no need to regulate the pressure down. Just install the bypass and let the CP3 take as much or as little as it needs.

#63

Took my truck in today for a leaky cp3 and took the time to explain everything I've learned about the subject to the diesel mech. there and he was impressed with the knowledge you guys have(told him where I'd learned it) and he said he would agree totally with everything I explained to him about the cp3 starving from the lift pump and said he would check the flow of the lift pump while he had it in there. Well, called to check on the truck and they said both of your new pumps will be in Thursday, seems the LP was getting weak too.  It's so nice to be informed, Thanks guys,LCH

It's so nice to be informed, Thanks guys,LCH

P.S. I'm gonna have a conversation with them about the walbro pump and my warranty, I don't want to lose another cp3 if I can help it.

It's so nice to be informed, Thanks guys,LCH

It's so nice to be informed, Thanks guys,LCH P.S. I'm gonna have a conversation with them about the walbro pump and my warranty, I don't want to lose another cp3 if I can help it.

#65

Registered User

Join Date: Dec 2002

Location: Long Island, NY

Posts: 741

Likes: 0

Received 0 Likes

on

0 Posts

Superduty...since you were/are a Ford guy if you go into the history and look at some of the lift pump solution the older pumps would not handle higher input pressures. it was damaging the injection pumps. Also i am not sure i understand what you are doing reguarding the pump pressure and fuel filter. you said anything more than 60psi would blow the fuel filter. doesnt this pump push more than that.

#66

Registered User

Originally Posted by DF5152

Superduty...since you were/are a Ford guy if you go into the history and look at some of the lift pump solution the older pumps would not handle higher input pressures. it was damaging the injection pumps. Also i am not sure i understand what you are doing reguarding the pump pressure and fuel filter. you said anything more than 60psi would blow the fuel filter. doesnt this pump push more than that.

#67

"doesnt this pump push more than that."

It will if you let it. I am suggesting that people put a bypass loop around the CP3 so that the fuel pressure is very low. The CP3 has a built in supply pump that will draw as much fuel into it as it needs. All you have to do is circulate fuel to the CP3 and it will take care of the rest.

The Walbro will develop 100 PSI if you put some restriction in the line. However, if you keep the filter clean and install the bypass line, you should see about 80 GPH going past the CP3 with only about 10 PSI of backpressure. This should be the best flow TO THE CP3 available from ANY pump combination. And even if the filter plugs and requires 40 PSI, the fuel flow to the CP3 will still be 60 GPH. With those other pumps, the fuel flow to the CP3 would stop.

"Superduty do you know how many lift pumps (percentage)are failing on the 3rd gens?" I dunno. Again I don't own a Dodge and I've run a Walbro since I put my engine in.

"How often are you changing your fuel filter if all the return fuel is running through it?"

It doesn't matter that all the fuel runs through the filter. It would all run through it sooner or later anyway. This has the advantage of getting your tank clean before the fuel is burnt. No sediment will build up in the tank over time with this system. The Ford system works this way too.

Maybe this explains the plumbing.

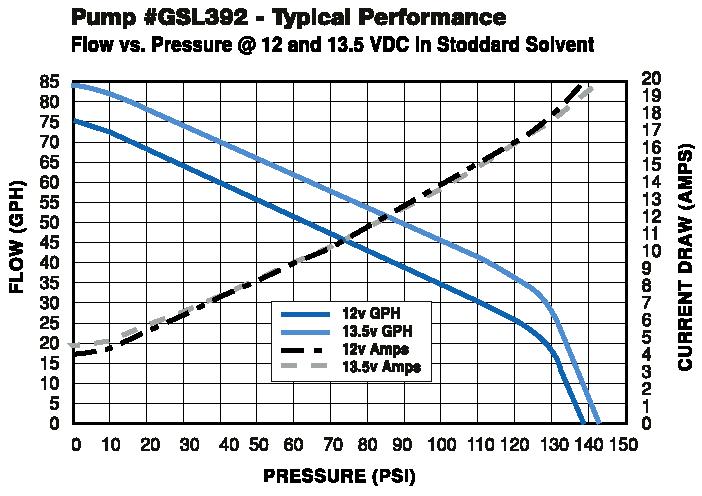

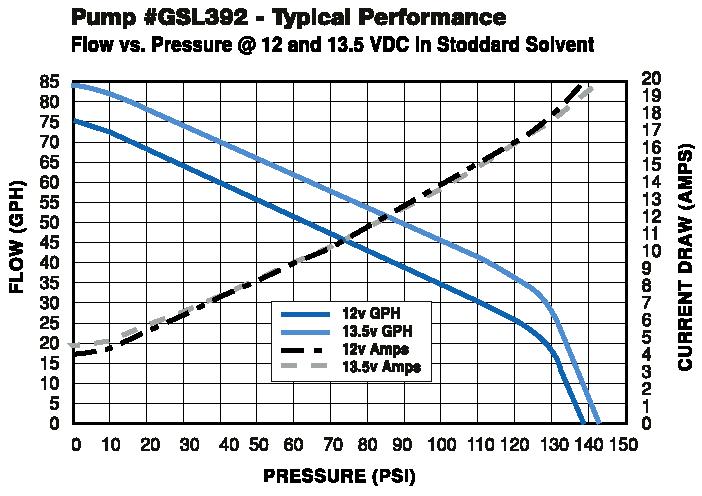

Here is the flow graph for the 392. Compare any other pump you are considering to this before you buy.

It will if you let it. I am suggesting that people put a bypass loop around the CP3 so that the fuel pressure is very low. The CP3 has a built in supply pump that will draw as much fuel into it as it needs. All you have to do is circulate fuel to the CP3 and it will take care of the rest.

The Walbro will develop 100 PSI if you put some restriction in the line. However, if you keep the filter clean and install the bypass line, you should see about 80 GPH going past the CP3 with only about 10 PSI of backpressure. This should be the best flow TO THE CP3 available from ANY pump combination. And even if the filter plugs and requires 40 PSI, the fuel flow to the CP3 will still be 60 GPH. With those other pumps, the fuel flow to the CP3 would stop.

"Superduty do you know how many lift pumps (percentage)are failing on the 3rd gens?" I dunno. Again I don't own a Dodge and I've run a Walbro since I put my engine in.

"How often are you changing your fuel filter if all the return fuel is running through it?"

It doesn't matter that all the fuel runs through the filter. It would all run through it sooner or later anyway. This has the advantage of getting your tank clean before the fuel is burnt. No sediment will build up in the tank over time with this system. The Ford system works this way too.

Maybe this explains the plumbing.

Here is the flow graph for the 392. Compare any other pump you are considering to this before you buy.

#68

Forgive me if I missed this somewhere, but you (Super Duty) say the banjo bolt would have to be machined. Could you use one like everyone's using to tap for a fuel pressure gauge. Then just thread in a hose barb fitting. Or would this set up be too restricive, or not work for some other reason. Thank's.

Like this one.

http://www.dieselmanor.com/dm_products/DM-DBBLT.asp

Like this one.

http://www.dieselmanor.com/dm_products/DM-DBBLT.asp

#69

"Forgive me if I missed this somewhere, but you (Super Duty) say the banjo bolt would have to be machined. Could you use one like everyone's using to tap for a fuel pressure gauge."

Yep, they would work perfectly.

"Then just thread in a hose barb fitting. Or would this set up be too restricive, or not work for some other reason. Thank's."

No, that is exactly what you want. There is nothing wrong with the bypass being a bit restrictive. 10-15PSI backpressure would be fine. But there isn't anything very restrictive about the banjo bolts shown there. The 3/4" bolt head might be a tight fit, but should be OK. Those banjo bolts are perfect.

Yep, they would work perfectly.

"Then just thread in a hose barb fitting. Or would this set up be too restricive, or not work for some other reason. Thank's."

No, that is exactly what you want. There is nothing wrong with the bypass being a bit restrictive. 10-15PSI backpressure would be fine. But there isn't anything very restrictive about the banjo bolts shown there. The 3/4" bolt head might be a tight fit, but should be OK. Those banjo bolts are perfect.

#70

Banned

Join Date: Apr 2004

Location: Where hell freezes over.

Posts: 1,410

Likes: 0

Received 0 Likes

on

0 Posts

O.k. know that you put a drawing in I can see how it will work. I thought you were by-passing right after the pump. This would also work o.k. for the Vp44 since the extra PSI is being blead off back to the tank. Note I'am confirming your right.

I still would not touch it if the truck is under warranty though. I have seen alot of lift pump set-ups and people trying to market different set-ups and I have yet to see one that did not have problems. Maybe not as many problems as DC's but still the others have failed from time to time too. Time will tell if your system is better then what others are marketing. I still have 91,000 miles of warranty and research before I become commited again. Maybe with the in-tank system I won't have to worry.

I still would not touch it if the truck is under warranty though. I have seen alot of lift pump set-ups and people trying to market different set-ups and I have yet to see one that did not have problems. Maybe not as many problems as DC's but still the others have failed from time to time too. Time will tell if your system is better then what others are marketing. I still have 91,000 miles of warranty and research before I become commited again. Maybe with the in-tank system I won't have to worry.

#71

Muted User

Join Date: Feb 2005

Location: "The Peoples Republic of Illinois".....behind enemy lines

Posts: 323

Likes: 0

Received 0 Likes

on

0 Posts

Now that I understand all the mounting and plumbing issues regarding this mod, I still have three more questions. I hope I didn't overlook the answers while reading here. 1. How is the Walbro pump wired into the system? 2. Is the OEM lift pump removable from the fuel filter housing? 3. If the OEM lift pump is removable, can the wiring that fed it be routed to the Walbro on the frame rail?? Thanks, it sounds like a super mod and I will do it once I can work outside without gloves on!!!!

#72

"1. How is the Walbro pump wired into the system?"

I dunno. I drive a Ford, remember ?

From putting the 05 Cummins in my Ford, I know that the ECM outputs a voltage to drive a relay that controls the fuel pump. BTW: The voltage is what is called "open collector" meaning it is kind of like a relay ground output, meaning that when the ECM wants the fuel pump to run it connects the fuel pump signal to ground. So there is probably a relay in the truck with one terminal of the coil connected to 12V and the other terminal to the ECM output. At least that is the way it works on my Ford and appears to work from the wiring diagrams in the 05 Dodge shop manual.

So... I suspect the Dodge trucks have a relay somewhere with one or two wires running to the fuel pump, be it on the engine (03.5) or the in tank fuel pump (05s). If the relay is strong enough, which I suspect it might be, then all you need to do is use the old fuel pump wires to power the Walbro.

"2. Is the OEM lift pump removable from the fuel filter housing?"

You must be speaking of an 03.5 fuel pump. Anything is removeable with the right "tool". BTW: when Dodge converts an 03.5 from an engine mounted lift pump to an in tank pump they must have a harness that rewires the fuel pump to be tank located.

"3. If the OEM lift pump is removable, can the wiring that fed it be routed to the Walbro on the frame rail??"

Probably. WIres may need to be extended. The Walbro has 2 terminals, PWR and GND. They are 6-32 screw terminals, if I remember correctly. The small eye rings work if you have to make up a harness.

I dunno. I drive a Ford, remember ?

From putting the 05 Cummins in my Ford, I know that the ECM outputs a voltage to drive a relay that controls the fuel pump. BTW: The voltage is what is called "open collector" meaning it is kind of like a relay ground output, meaning that when the ECM wants the fuel pump to run it connects the fuel pump signal to ground. So there is probably a relay in the truck with one terminal of the coil connected to 12V and the other terminal to the ECM output. At least that is the way it works on my Ford and appears to work from the wiring diagrams in the 05 Dodge shop manual.

So... I suspect the Dodge trucks have a relay somewhere with one or two wires running to the fuel pump, be it on the engine (03.5) or the in tank fuel pump (05s). If the relay is strong enough, which I suspect it might be, then all you need to do is use the old fuel pump wires to power the Walbro.

"2. Is the OEM lift pump removable from the fuel filter housing?"

You must be speaking of an 03.5 fuel pump. Anything is removeable with the right "tool". BTW: when Dodge converts an 03.5 from an engine mounted lift pump to an in tank pump they must have a harness that rewires the fuel pump to be tank located.

"3. If the OEM lift pump is removable, can the wiring that fed it be routed to the Walbro on the frame rail??"

Probably. WIres may need to be extended. The Walbro has 2 terminals, PWR and GND. They are 6-32 screw terminals, if I remember correctly. The small eye rings work if you have to make up a harness.

#73

"Time will tell if your system is better then what others are marketing."

My system has only 2 non stock components. The CP3 bypass. Not a lot to go wrong there. And the Walbro pump.

I've been running a Walbro pump in my SD since 2000 or 2001 (can't remember when) at 75 PSI. About 60,000 miles.

Show me ANY fuel pump that has been run on a Dodge at anywhere near these pressures for anywhere near this long and I'll start worrying. Go back and read my spiel on the Walbro being cooled and lubricated by fuel versus other pumps (including the stocker) being air cooled and totally enclosed.

If you really want to leave DC no squirm room with the warranty, put a BOSCH pump on your truck. You can get one from any FORD dealer as a '99 and newer stock PSD fuel pump. Roughly the same size as the Walbro pump (little larger in diameter, same terminals) lower shut off pressure, lower volume. I think they retail for about $250. They rarely fail on PSD trucks and they run at 60 PSI all the time.

My system has only 2 non stock components. The CP3 bypass. Not a lot to go wrong there. And the Walbro pump.

I've been running a Walbro pump in my SD since 2000 or 2001 (can't remember when) at 75 PSI. About 60,000 miles.

Show me ANY fuel pump that has been run on a Dodge at anywhere near these pressures for anywhere near this long and I'll start worrying. Go back and read my spiel on the Walbro being cooled and lubricated by fuel versus other pumps (including the stocker) being air cooled and totally enclosed.

If you really want to leave DC no squirm room with the warranty, put a BOSCH pump on your truck. You can get one from any FORD dealer as a '99 and newer stock PSD fuel pump. Roughly the same size as the Walbro pump (little larger in diameter, same terminals) lower shut off pressure, lower volume. I think they retail for about $250. They rarely fail on PSD trucks and they run at 60 PSI all the time.

#74

"Superduty, did you check with the fuel filter manufacturer to see what kind of pressure it is rated for? That is the only problem I can see with your setup diagram. The higher pressure and flow may compromise the filtering and water stripping abilities of the filter setup."

The only thing I am worried about is the Walbro bursting the fuel filter element if it gets too plugged.

I am going to put a gauge on the inlet to the filter housing and monitor the back pressure. I'll change the filter when the backpressure is 20 ish PSI.

The only thing I am worried about is the Walbro bursting the fuel filter element if it gets too plugged.

I am going to put a gauge on the inlet to the filter housing and monitor the back pressure. I'll change the filter when the backpressure is 20 ish PSI.

#75

Banjo fittings:

http://www.genosgarage.com/CoastalD..._ID=593&CATID=1

Regulators:

http://www.swagelok.com/search/site...RT=0&PG=0&RPR=0

http://www.swagelok.com/shopping/pr...RT=0&PG=0&RPR=0

You have to disconnect the line to set the pressure with these. But they are very compact, just a 1/4" nipple is all.

Could use a Holley type as well.

I have no affiliation with Swagelock. I just like their stuff. Ditto Bosch, Walbro, Geno, etc.

www.mcmaster-carr.com as well, but I couldn't find any that are adjustable.

http://www.genosgarage.com/CoastalD..._ID=593&CATID=1

Regulators:

http://www.swagelok.com/search/site...RT=0&PG=0&RPR=0

http://www.swagelok.com/shopping/pr...RT=0&PG=0&RPR=0

You have to disconnect the line to set the pressure with these. But they are very compact, just a 1/4" nipple is all.

Could use a Holley type as well.

I have no affiliation with Swagelock. I just like their stuff. Ditto Bosch, Walbro, Geno, etc.

www.mcmaster-carr.com as well, but I couldn't find any that are adjustable.