Fuel System Low Pressure Bleed Screw

#1

Troubles w. Fuel System Low Pressure Bleed Screw

Hey folks, HELP! you know that little bleed screw that sits inside the banjo bolt right above the fuel filter in these first gen dodge cummins'. I have been having a leaking problem out of mine. Cross threaded the old one so went to Cummins and got replacement parts. I have now done that a third time figuring it has all been my own mistakes, but no matter how tight or loose I seat that bleeder screw in the banjo bolt, they continue to leak. I have tried to go at it by tightening it very slow, like 1/16th of a turn at a time and I can't get it to completely shut off the drip. Of course, if you tighten it too far, then the little bleeder screw cross threads sits in there and spins and leaks even worse and becomes difficult to extract . I have checked very carefully with a flashlight to see that it is leaking out at the neck of the little screw and it is. I have spent $100 buying the stuff to try and do it right with three new sets of bolts already. Nobody at cummins is very helpful or seems to know much about it. Ive already posted one thread on on another forum and got no responses. I've asked Cummins if there is supposed to be a gasket/washer sealer on that bleeder screw and had one guy tell me no, and another tell me yes, but that guy sent me a completely irrelevant part. I'm at a loss. Any body know the part #'s for that bleed screw and banjo bolt. Now I think those dingdongs on the other end of the line have been sending me the wrong bleeder screw all along. I know I'm a dingdong too when it comes to this stuff, but jeepers those guys have been rude and unhelpful.

Any help would be much appreciated

Any help would be much appreciated

#4

Registered User

I bought the replacement banjo from Geno's with the 1/8 inch pipe thread and a plug so I could plumb in a pressure gauge. I didn't leave the gauge in place though and use the plug with a bit of Teflon(tm) tape to seal it.

Edwin

Edwin

#5

Registered User

I usually replace them with the Geno's bolt and put in a gauge.

#6

DTR's "Cooler than ice cubes 14 miles North of North Pole" member

Join Date: Oct 2006

Location: 14mi North of North Pole

Posts: 1,797

Likes: 0

Received 9 Likes

on

8 Posts

Ever thought of just ditching the hard line and installing a couple of metric adapters and some -AN fittings? You don't really need a bleed screw there anyways.

If I remember right, you need 1 M12 and 1 M14 fitting then whatever AN lines you would like.

If I remember right, you need 1 M12 and 1 M14 fitting then whatever AN lines you would like.

#7

Registered User

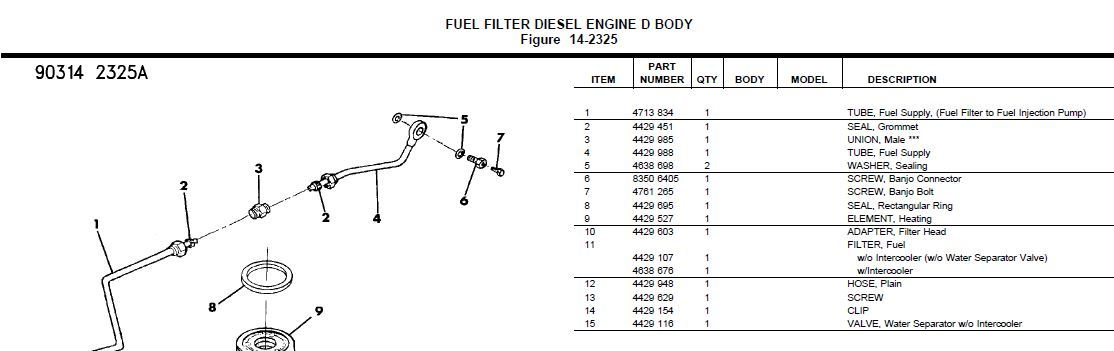

IMG 2510

Find #6 and 7 are valid MOPAR part numbers. 6 is a banjo bolt (used with 2 copper washers/gaskets) and 7 is a bleeder type screw, needle valve end. Just snug on 7 should seal it up tight. Over tightening it will damage the needle/seat valve part of it. Both fit 1990-1993 CTD's.

I usually replace them with the Geno's bolt and put in a gauge.

I usually replace them with the Geno's bolt and put in a gauge.

Trending Topics

#8

Registered User

There's supposed to be a small washer under that bleeder screw.

Cummins parts list describes it as a "captive washer cap screw." Doesn't specify the material, copper, etc.

Cummins parts list describes it as a "captive washer cap screw." Doesn't specify the material, copper, etc.

#9

Registered User

Yep, it should have a small copper washer under it. Hopefully the copper washer assortment kits you can buy will have the proper size included. I've replaced a few in the past, but can't remember where the replacements came from.

#10

Thanks for all this everybody. I have now discovered that the Cummins shop I have been dealing with sent me the wrong part for the bleeder screw to begin with and it almost worked right but not quite which is why I was so confused. When I called and attempted to resolve the issue they were very assured that I was just doing it wrong. Therefore; me trying again with the same set of parts twice. Now that I know this, with some research I found that there is a bleeder screw, part # 393570 that is carried by cummins and Geno's garage that looks to be the right one and comes with the copper washer as a couple folks had mentioned. The one they were pushing on me was part #3905307 which I now believe is an injector return line banjo connector). They were also telling me it didn't require a washer. Everybody's input here has been very helpful. Thanks! I'm gonna talk to a manager and try and get my money back and get the right parts from them since I have now paid for them 3 times over...We shall see. If not I'll shop at Geno's. I've heard good things. Like the idea of easily connecting a pressure gauge there.

#11

Registered User

Go with #3939570. While a different part number, it's identical to #3905403 in shank, pitch and length and at least by the picture on Geno's, it has the copper washer.

#3905403 is the fuel filter plumbing bleeder screw.

#3905307 is the injector return banjo.

Funny, they're both the same shank and pitch but lengths are 4mm different from one another. There's not a listing for a copper washer at all.

I wouldn't at all hesitate to order from Geno's. I've ordered numerous parts from them plenty of times and have nothing bad to say about the folks there.

#3905403 is the fuel filter plumbing bleeder screw.

#3905307 is the injector return banjo.

Funny, they're both the same shank and pitch but lengths are 4mm different from one another. There's not a listing for a copper washer at all.

I wouldn't at all hesitate to order from Geno's. I've ordered numerous parts from them plenty of times and have nothing bad to say about the folks there.

#12

I ended up going this route. Haven't yet ordered a pressure gauge. the guy on the phone was recommending I go electric with the gauge. I'm not sure he understood this system. I was assuming the pressure gauge you used is mechanical. Is that correct? It seems like it would very simply be driven by the pressure that is on the system right there and mostly for awareness of the pressure coming off the lift pump. Am I on the right track with my thinking?

#13

Registered User

I ended up going this route. Haven't yet ordered a pressure gauge. the guy on the phone was recommending I go electric with the gauge. I'm not sure he understood this system. I was assuming the pressure gauge you used is mechanical. Is that correct? It seems like it would very simply be driven by the pressure that is on the system right there and mostly for awareness of the pressure coming off the lift pump. Am I on the right track with my thinking?

To use a mechanical gauge in the cockpit you would need an isolator the cost of which makes the cost of an electric gauge more reasonable. YMMV.

Edwin

#15

Administrator