Broke a screw but beat a powerstroke

#1

Registered User

Thread Starter

Join Date: Sep 2007

Location: McCall, Idaho

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

Broke a screw but beat a powerstroke

So today i got my truck dialed in just perfict at 25-28psi and no more than 1250 on the pyro and i was puting a couple of nuts back in the side of the pump that i had removed prior to get to the fuel screw, i snaped the screw thats on the top of the pump and holds a small hose that goes from the intake manifold to the pump. the screw has a hole through it and now that its broke, i can hear the air coming out of it when the turbo spools up. Where can i get a new one? The funny thing is after this happend, my buddy just bought an 02 powerstroke with an exsaust and intake and wanted to race, we raced 4 times and i walked away from him with ease every time . It was awsome. Thank god for cummins motors

. It was awsome. Thank god for cummins motors

. It was awsome. Thank god for cummins motors

. It was awsome. Thank god for cummins motors

#2

Registered User

Join Date: Feb 2007

Location: Pen Argyl Pennsylvania

Posts: 1,540

Likes: 0

Received 0 Likes

on

0 Posts

That screw is what sends the pressure to the pump to move the fuel pin. Without it the pin doesn't move much if at all. As far as where to get one I would check a Cummins dealer or a Dodge dealer that can get you Cummins part.

Congrats on the KILL just think how bad you would have walked away if everything was perfect on your truck.

Ryan

Congrats on the KILL just think how bad you would have walked away if everything was perfect on your truck.

Ryan

#3

Registered User

Thread Starter

Join Date: Sep 2007

Location: McCall, Idaho

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

gosh i had no idea thats what that did. Thanx for the info tho, i cant belive that it was still runing that strong and that well! i did notice however that there wasnt as much smoke and that the throtle response was a bit soft. So you dont think that i can find that screw at a parts shack? Can i make one? Cause there isnt a dodge dealership for 30 miles. Is it bad to drive it a lot with it like this?

thats what that did. Thanx for the info tho, i cant belive that it was still runing that strong and that well! i did notice however that there wasnt as much smoke and that the throtle response was a bit soft. So you dont think that i can find that screw at a parts shack? Can i make one? Cause there isnt a dodge dealership for 30 miles. Is it bad to drive it a lot with it like this?

thats what that did. Thanx for the info tho, i cant belive that it was still runing that strong and that well! i did notice however that there wasnt as much smoke and that the throtle response was a bit soft. So you dont think that i can find that screw at a parts shack? Can i make one? Cause there isnt a dodge dealership for 30 miles. Is it bad to drive it a lot with it like this?

thats what that did. Thanx for the info tho, i cant belive that it was still runing that strong and that well! i did notice however that there wasnt as much smoke and that the throtle response was a bit soft. So you dont think that i can find that screw at a parts shack? Can i make one? Cause there isnt a dodge dealership for 30 miles. Is it bad to drive it a lot with it like this?

#4

Registered User

Join Date: Feb 2007

Location: Pen Argyl Pennsylvania

Posts: 1,540

Likes: 0

Received 0 Likes

on

0 Posts

You might be able to take the pieces to a parts store and have them try to find a brake line bolt (caliper to line bolt) that will work. I don't think it'll hurt to drive but if it were me I would fix it first.

I also believe that they are metric threads but I'm not positive.

The problem with trying to fix it is that it is a hollow bolt with two hole at the end by the head and it will be week not to mention if you weld it up it may not seal properly.

Ryan

I also believe that they are metric threads but I'm not positive.

The problem with trying to fix it is that it is a hollow bolt with two hole at the end by the head and it will be week not to mention if you weld it up it may not seal properly.

Ryan

#5

Registered User

Thread Starter

Join Date: Sep 2007

Location: McCall, Idaho

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

yeah i dont want to drive it but i dont have much else other choise its all i got but ill take your idea to the parts shack and see what they may be able to do for me. The screw is a 12mm metric.

#6

Administrator

A good supply of those Banjo bolts, washers and lines are at your local Pick-N-whateveryoucallitwhereyouare.

Check out any of the foreign cars like Volvo, VW Rabbits, and Saab from the 70's, 80's and 90's

They use Bosch fuel injection systems and the Banjo and braided lines are all over the engine compartment. They also use a Banjo fitting that has a Nylon line heat crimped to the fitting that is perfect for a hose connection.

Also while you are there load up your pockets with Bosch ISO relays and mating sockets.

Jim

Check out any of the foreign cars like Volvo, VW Rabbits, and Saab from the 70's, 80's and 90's

They use Bosch fuel injection systems and the Banjo and braided lines are all over the engine compartment. They also use a Banjo fitting that has a Nylon line heat crimped to the fitting that is perfect for a hose connection.

Also while you are there load up your pockets with Bosch ISO relays and mating sockets.

Jim

#7

Registered User

Join Date: Dec 2005

Location: SW Michigan

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

You won't find that part anywhere but Cummins or what he said about a Bosch filled junk yard.

Here is the Cummins Banjo Bolt Part # 3924724

I want to say it was about $14. My nearest Cummins service center had it to me next day.

Others have redone that hose with an American threaded fitting that is close.

-Steve

Here is the Cummins Banjo Bolt Part # 3924724

I want to say it was about $14. My nearest Cummins service center had it to me next day.

Others have redone that hose with an American threaded fitting that is close.

-Steve

Trending Topics

#8

Registered User

Not sure if it was this forum or another but I remember a thread about using air fittings and maybe 1/8" line? There was some concern that the smaller line might slow the response some.

#10

1st Generation Admin

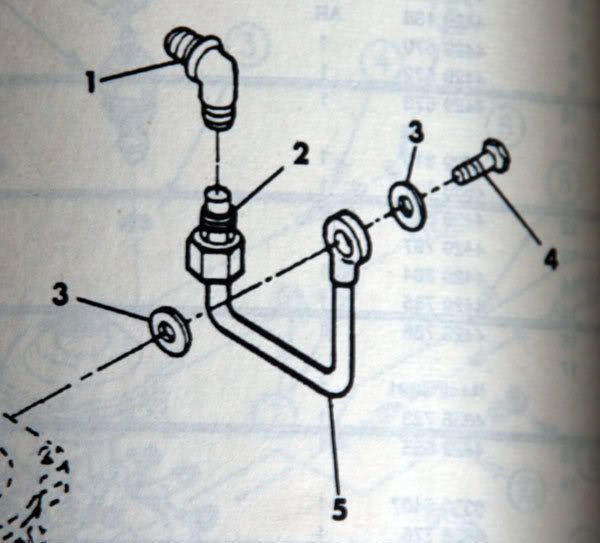

Thanks for the advice everyone, I chose the DIY route. NAPA had just what I needed. here it is with a parts list.

AFC (air fuel control) boost pressure line repair

1. 1/4 NPT male - 1/4 OD air line coupling, 90 degree, (intake side) NAPA # 1460 x 1

2. AFC matching thread (1/8 inch fine?) - 1/4 OD air line, straight, NAPA # 1468 x 4 x 1

3.1/4 OD black nylon air line, NAPA # D1040401

(no thread tape the brass sealed it right up!)

(the NAPA #'s are off the invoice, may be local, #'s may differ)

Truck acts like a rocket now, escpecially in 3rd at 1800-2000

(compared to were it was).

(compared to were it was).

AFC (air fuel control) boost pressure line repair

1. 1/4 NPT male - 1/4 OD air line coupling, 90 degree, (intake side) NAPA # 1460 x 1

2. AFC matching thread (1/8 inch fine?) - 1/4 OD air line, straight, NAPA # 1468 x 4 x 1

3.1/4 OD black nylon air line, NAPA # D1040401

(no thread tape the brass sealed it right up!)

(the NAPA #'s are off the invoice, may be local, #'s may differ)

Truck acts like a rocket now, escpecially in 3rd at 1800-2000

(compared to were it was).

(compared to were it was).

#12

Registered User

Join Date: Dec 2006

Location: Tennessee

Posts: 398

Likes: 0

Received 0 Likes

on

0 Posts

well the only problem is with the above post is that the manifold itself is 1/8 npt and the afc housing is 1/16 npt i believe, so you can fix it all with some 1/4" ID lines. very easy cheap install, i think it cost me $6

#13

Registered User

Thread Starter

Join Date: Sep 2007

Location: McCall, Idaho

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

ok so first of all thank you guys for all of your imput and help. i did the excact idea from the picture above and it is killer fast now!!!! i got the pump and throtle dialed in perfict im hitin 27psi and no more than 1250 on the pyro and thats when i hold it wide open for a mile straight so i think its doin great. Any more imput you guys can give me at all i would love to hear and do. My only question is, the hose that i used to go from the manifold to pump, if i make it shorter would that make it faster? Cause i actualy did it a little differently i didnt use any 90 degree fitings i used straight fittings i was just wondering thanx again

#14

Chapter President

Join Date: Nov 2005

Location: Ridgecrest, CA

Posts: 858

Likes: 0

Received 0 Likes

on

0 Posts

Glad my repair/ photo could be of use. ( even if BC beat me to posting it, haven't been on much latley

( even if BC beat me to posting it, haven't been on much latley ) I used the 90 because its all NAPA had at the time. I have heard some guys say that the size of line is a factor and also the length. I am not sure. I know that it is boost pressure related. With water lines pressure and flow are too different things even though they work together, (ie, a closed line will read high pressure but if the flow is low as soon as the valve is opened the pressure drops to almost nothing, air is compressable, that may factor in, a shorter distance may result in less travel time for the boost, but if the system is closed, once the turbo spools up and makes boost the whole system should be charged to same psi, from the turbo outlet to the intake valve, all at the same time.

) I used the 90 because its all NAPA had at the time. I have heard some guys say that the size of line is a factor and also the length. I am not sure. I know that it is boost pressure related. With water lines pressure and flow are too different things even though they work together, (ie, a closed line will read high pressure but if the flow is low as soon as the valve is opened the pressure drops to almost nothing, air is compressable, that may factor in, a shorter distance may result in less travel time for the boost, but if the system is closed, once the turbo spools up and makes boost the whole system should be charged to same psi, from the turbo outlet to the intake valve, all at the same time. Maybe I am wrong, I know there are plenty of guys here who know more than me, and they will probably correct me, this is just how I understand it to be.

Maybe I am wrong, I know there are plenty of guys here who know more than me, and they will probably correct me, this is just how I understand it to be. Hope it helps!! and I hope somebody sets me straight if its way out there

Hope it helps!! and I hope somebody sets me straight if its way out there

( even if BC beat me to posting it, haven't been on much latley

( even if BC beat me to posting it, haven't been on much latley ) I used the 90 because its all NAPA had at the time. I have heard some guys say that the size of line is a factor and also the length. I am not sure. I know that it is boost pressure related. With water lines pressure and flow are too different things even though they work together, (ie, a closed line will read high pressure but if the flow is low as soon as the valve is opened the pressure drops to almost nothing, air is compressable, that may factor in, a shorter distance may result in less travel time for the boost, but if the system is closed, once the turbo spools up and makes boost the whole system should be charged to same psi, from the turbo outlet to the intake valve, all at the same time.

) I used the 90 because its all NAPA had at the time. I have heard some guys say that the size of line is a factor and also the length. I am not sure. I know that it is boost pressure related. With water lines pressure and flow are too different things even though they work together, (ie, a closed line will read high pressure but if the flow is low as soon as the valve is opened the pressure drops to almost nothing, air is compressable, that may factor in, a shorter distance may result in less travel time for the boost, but if the system is closed, once the turbo spools up and makes boost the whole system should be charged to same psi, from the turbo outlet to the intake valve, all at the same time. Maybe I am wrong, I know there are plenty of guys here who know more than me, and they will probably correct me, this is just how I understand it to be.

Maybe I am wrong, I know there are plenty of guys here who know more than me, and they will probably correct me, this is just how I understand it to be. Hope it helps!! and I hope somebody sets me straight if its way out there

Hope it helps!! and I hope somebody sets me straight if its way out there

#15

Registered User

Join Date: Feb 2011

Location: lemont il

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

ok, im doing dieselcarpenter's repair,i went to ACE, carquest and a small motor repair place to find the fitting and had no luck. so i went to napa and ordered the 1468 x4 x 1 part number and the made me order a package of 5 them. so i now have 4 extra of that part number. would anyone have any interest in me buying more line and the other fittings and putting a kit together. so you guys dont have to search for the fittings and buy a package of 5 fittings like i did? i dont wanna make any money i just want to get my money back from buying the package and want to make it easier on you 1st gen fans.