Need Help w/gauge install today?

#31

Registered User

Join Date: Mar 2002

Location: The Great Northwest!

Posts: 1,276

Likes: 0

Received 0 Likes

on

0 Posts

The fabric sleeves are included from the gauge manufacturer so we just throw them in the kits. I do not use them in the shop. The 2 long heat shrink strips simply get cut in half, for a total of 4.

I use a mini fuse tap at #5 for illumination. I tap the FUSED side though! This is important to protect the wiring of the truck!

Power can come from a few sources, but the ignition fuse is a good one as well.

Dave

I use a mini fuse tap at #5 for illumination. I tap the FUSED side though! This is important to protect the wiring of the truck!

Power can come from a few sources, but the ignition fuse is a good one as well.

Dave

#32

Registered User

Join Date: Oct 2007

Location: Okotoks, AB

Posts: 1,716

Likes: 0

Received 0 Likes

on

0 Posts

#33

Registered User

Join Date: Dec 2008

Location: Lynden WA

Posts: 190

Likes: 0

Received 0 Likes

on

0 Posts

#34

Registered User

Thread Starter

Just go slow and only run the tap 3/4 of the way in. If you go past that the fitting wont tighten enough. When I was drilling and tapping I had a buddy hold a shop vac to suck up all the cuttings. I cleaned the hole out using a q-tip with some grease on it. Just go slow and youll be ok.

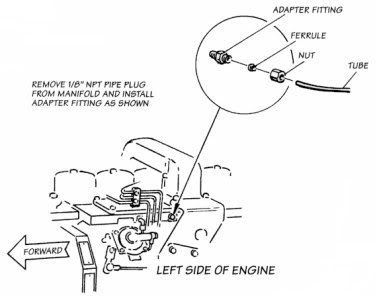

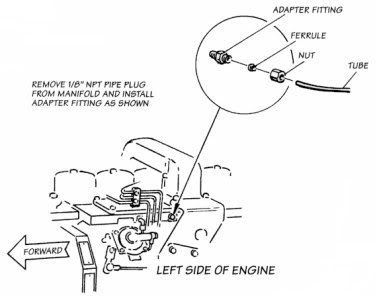

Boost guage hookup:

Fuel Pressure hookup:

Boost guage hookup:

Fuel Pressure hookup:

#36

Registered User

Thread Starter

Thread sealants

Erik at Vulcan gave me instructions re: thread sealants, but I'd like to confirm because it was a little confusing...Hopefully Vulcan or someone who has installed their gauge set up can confirm for me...

Fuel line: the brass banjo bolt going into the fuel return line doesn't use any sealant--it has 2 washers.

the adaptor coming out of the banjo bolt, toward the gauge, has fine threads, and needs diesel rated thread sealant (I think permatex 59214)

the other side of that adaptor, going into the fuel hose (mine has a more coarse thread) does not call for any thread sealant, but it is ok to put a little oil (would anti seize be ok?)

The other side of the fuel hose is male with the finer threads, it goes into the isolator. This calls for diesel rated thread sealant.

Also the brass threaded male leaving the isolator towards the gauge would need diesel rated thread sealant.

A male push fitting screws into the isolator gauge end, and it is already threaded.

Finally, at the gauge, there is the 90* female that threads onto the brass male gauge nipple (finer type thread) and that requires the diesel rated sealant.

BOOST LINE

The fine threaded brass adaptor going into the requires thread sealant.

The push fitting supplied already has taped threads.

The elbow at the boost gauge is the same as the fuel elbow--

pre taped push fitting onto male brass threads from gauge.

I know this is laborious, but if there's every anybody as green as I am at this stuff, it will probably help them as well.

I really appreciate everybody's patience with me

Fuel line: the brass banjo bolt going into the fuel return line doesn't use any sealant--it has 2 washers.

the adaptor coming out of the banjo bolt, toward the gauge, has fine threads, and needs diesel rated thread sealant (I think permatex 59214)

the other side of that adaptor, going into the fuel hose (mine has a more coarse thread) does not call for any thread sealant, but it is ok to put a little oil (would anti seize be ok?)

The other side of the fuel hose is male with the finer threads, it goes into the isolator. This calls for diesel rated thread sealant.

Also the brass threaded male leaving the isolator towards the gauge would need diesel rated thread sealant.

A male push fitting screws into the isolator gauge end, and it is already threaded.

Finally, at the gauge, there is the 90* female that threads onto the brass male gauge nipple (finer type thread) and that requires the diesel rated sealant.

BOOST LINE

The fine threaded brass adaptor going into the requires thread sealant.

The push fitting supplied already has taped threads.

The elbow at the boost gauge is the same as the fuel elbow--

pre taped push fitting onto male brass threads from gauge.

I know this is laborious, but if there's every anybody as green as I am at this stuff, it will probably help them as well.

I really appreciate everybody's patience with me

#37

Registered User

Join Date: Jul 2003

Location: The Great White North

Posts: 7,129

Likes: 0

Received 0 Likes

on

0 Posts

#38

Registered User

Join Date: Jul 2003

Location: The Great White North

Posts: 7,129

Likes: 0

Received 0 Likes

on

0 Posts

As for the thread sealant - use #2 Permatex or Loctite PST (teflon paste). Hard to answer your question without seeing all of fittings etc. - but use the thread sealant on any of the fittings that are NPT.

#39

Registered User

Thread Starter

[quote=Dr. Evil;2511730]No that is the banjo bolt on the inlet of the injection pump. It its drilled and tapped 1/8" NPT just like you did with your exhaust manifold. =quote]

I just remove the plug from the bottom of that inlet and insert my banjo bolt into that fitting, right? I don't have to tap a new hole, right?

I just remove the plug from the bottom of that inlet and insert my banjo bolt into that fitting, right? I don't have to tap a new hole, right?

#40

Registered User

Join Date: Dec 2008

Location: Lynden WA

Posts: 190

Likes: 0

Received 0 Likes

on

0 Posts

If you have a tapped banjo bolt then no, just replace the stock one with the one already tapped. if it is not tapped pull it out and then just drill and tap it. (trick) if ya flip the banjo bolt upside down in the vise the drill bit fits right inside the center passage and it acts as a center. then just tap it out from the other side so the taper on the threads is correct. Clean it REALLY good after drilling and tapping, you are working on the clean side of the filter so make sure everything stays spotless.

#41

Registered User

Join Date: Jul 2003

Location: The Great White North

Posts: 7,129

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=barngal6;2511992]

Yes.

But, it really depends on where you got your tapped banjo bolt - most of them available from suppliers are 12mm and for the 24Vs. Did you get an actual 14mm banjo bolt for a 12V? if not, you might have to tap it yourself.

Be careful not to loose the washers, if you dont have any new ones on hand.

No that is the banjo bolt on the inlet of the injection pump. It its drilled and tapped 1/8" NPT just like you did with your exhaust manifold. =quote]

I just remove the plug from the bottom of that inlet and insert my banjo bolt into that fitting, right? I don't have to tap a new hole, right?

I just remove the plug from the bottom of that inlet and insert my banjo bolt into that fitting, right? I don't have to tap a new hole, right?

But, it really depends on where you got your tapped banjo bolt - most of them available from suppliers are 12mm and for the 24Vs. Did you get an actual 14mm banjo bolt for a 12V? if not, you might have to tap it yourself.

Be careful not to loose the washers, if you dont have any new ones on hand.

#42

Registered User

Thread Starter

[quote=Dr. Evil;2512090]

Yes.

But, it really depends on where you got your tapped banjo bolt - most of them available from suppliers are 12mm and for the 24Vs. Did you get an actual 14mm banjo bolt for a 12V? if not, you might have to tap it yourself.

Be careful not to loose the washers, if you dont have any new ones on hand.

Rats, the supplied banjo bolt IS a 12mm...but since I dropped the push fitting from the boost bolt and can't find it, guess I have time to hunt for a 14mm banjo bolt...

Yes.

But, it really depends on where you got your tapped banjo bolt - most of them available from suppliers are 12mm and for the 24Vs. Did you get an actual 14mm banjo bolt for a 12V? if not, you might have to tap it yourself.

Be careful not to loose the washers, if you dont have any new ones on hand.

#43

Registered User

Join Date: Jul 2003

Location: The Great White North

Posts: 7,129

Likes: 0

Received 0 Likes

on

0 Posts

You can just tap the one you have - or you might have to go directly to Cummins.

The 14mm tapped bolts are harder to find (I got mine from Infidel )

)

The 14mm tapped bolts are harder to find (I got mine from Infidel

)

)

#44

Registered User

Thread Starter

My fuel line from the fuel strainer to lift pump is really constricted even though its 1/2" line, so I'm going to fix that first, then add the fuel gauge after I sort thru changing that...