Official DTR Members "Twins" Club

#196

DTR 1st Sergeant

Thread Starter

I don't have a pic of mine

But there is a very nice pic of it on PDR website

I have the towing twins, but they were customized from the standard kit.

Of course, all of Nathan's are custom.

But there is a very nice pic of it on PDR website

I have the towing twins, but they were customized from the standard kit.

Of course, all of Nathan's are custom.

#197

Registered User

Join Date: Apr 2003

Location: Cummins Technical Center, IN

Posts: 6,564

Likes: 0

Received 6 Likes

on

5 Posts

Velocity in the cold pipe means almost nothing apart from how it affects pressure.

For the most part, cold pipe diameter is much ado about nothing, but you can "optimize" it.

Look at your big turbo closely. You'll see that the air is actually compressed in the "snail" of the compressor housing, but it's also accelerated tangentially as well. You'll notice that your big turbo's snail increases in area right up to the turbo discharge. This is called a diffuser in the aero world. It's the opposite of a nozzle (for subsonic flow).

So the larger the conduit for the flow, the slower it moves, but as it slows, it cools off and becomes more uniform.

Personally, I think that the cold piping should be the same size as the primary's outlet, then adapted to the secondary's inlet with a diffuser at the end. So if you have a 3.5" primary discharge, use 3.5" cold piping until either just before the last bend into the secondary's inlet, or just after.

Why? First, by keeping the cold piping no smaller than the primary's discharge, you've effectively eliminated any meaningful restriction. Second, by keeping the area smaller, you'll increase the temperature in the cold pipe, which is good-- because it increases heat rejection to the environment, giving you a slight intercooling effect. Finally, the diffuser at the end of the cold pipe will increase static pressure at the secondary's inlet, because it trades dynamic pressure for static pressure at the inlet (Bournoulli) and you'll see a drop in temperature right at the secondary's inlet.

I know it doesn't make sense that increasing the area of the conduit right before the secondary would INCREASE pressure, but it does. Normally, we think of expanding the volume as DEcreasing pressure. But in this case, it's not the change in VOLUME that we care about-- it's the cross-sectional area, which is determining the velocity for the incoming flow. Aerodynamics teaches us that as velocity increases, statid pressure goes DOWN and vice versa. So if we want maximum static pressure at the secondary's inlet (and we do!), then we also want the flow to be slow to the inlet, not fast.

So, run primary-outlet-sized tubing to the the secondary, but expand the conduit size to meet the secondary's inlet diameter, and do it as gradually as you can within the packaging limitations.

The pics I've seen of the BD twins illustrate the "right" way to plumb the line, imo. The transition they use is nice and gradual.

Justin

For the most part, cold pipe diameter is much ado about nothing, but you can "optimize" it.

Look at your big turbo closely. You'll see that the air is actually compressed in the "snail" of the compressor housing, but it's also accelerated tangentially as well. You'll notice that your big turbo's snail increases in area right up to the turbo discharge. This is called a diffuser in the aero world. It's the opposite of a nozzle (for subsonic flow).

So the larger the conduit for the flow, the slower it moves, but as it slows, it cools off and becomes more uniform.

Personally, I think that the cold piping should be the same size as the primary's outlet, then adapted to the secondary's inlet with a diffuser at the end. So if you have a 3.5" primary discharge, use 3.5" cold piping until either just before the last bend into the secondary's inlet, or just after.

Why? First, by keeping the cold piping no smaller than the primary's discharge, you've effectively eliminated any meaningful restriction. Second, by keeping the area smaller, you'll increase the temperature in the cold pipe, which is good-- because it increases heat rejection to the environment, giving you a slight intercooling effect. Finally, the diffuser at the end of the cold pipe will increase static pressure at the secondary's inlet, because it trades dynamic pressure for static pressure at the inlet (Bournoulli) and you'll see a drop in temperature right at the secondary's inlet.

I know it doesn't make sense that increasing the area of the conduit right before the secondary would INCREASE pressure, but it does. Normally, we think of expanding the volume as DEcreasing pressure. But in this case, it's not the change in VOLUME that we care about-- it's the cross-sectional area, which is determining the velocity for the incoming flow. Aerodynamics teaches us that as velocity increases, statid pressure goes DOWN and vice versa. So if we want maximum static pressure at the secondary's inlet (and we do!), then we also want the flow to be slow to the inlet, not fast.

So, run primary-outlet-sized tubing to the the secondary, but expand the conduit size to meet the secondary's inlet diameter, and do it as gradually as you can within the packaging limitations.

The pics I've seen of the BD twins illustrate the "right" way to plumb the line, imo. The transition they use is nice and gradual.

Justin

#198

Registered User

Join Date: Apr 2003

Location: Cummins Technical Center, IN

Posts: 6,564

Likes: 0

Received 6 Likes

on

5 Posts

OK, so the BD twins "ain't what they used to be". Or my memory is even worse than normal.

Here's the pic off their site as of today:

The transition the the top charger isn't as smooth as I remember-- maybe I'm thinking of someone else?

Anyway, the cold piping is well done, but the transition to the top charger isn't as good as it could be.

See how the pipe flares out as it goes into the (edit: SMALL) turbo? This is what needs to be done, but done better. The transition here is too abrupt. The transition angle here is probably more than 30º. You want this angle as low as possible.(edit: not)

EDIT: You don't really want the angle as small as possible-- this is wrong info. The angle for a diffuser should be as high as you can get WITHOUT getting separation of the flow. So the optimum diffuser angle is a function of flow velocity-- the faster the velocity, the less angle can be used before separation sets in.

If they had started the transition back before the visible weld bead, you'd have a much more gradual angle that would reduce or eliminate flow separation which increases drag in the conduit and leads to small eddy currents forming at the transition point.

I'll see if i can find the pic of the "right" twins I'm thinking of.

Here's the pic off their site as of today:

The transition the the top charger isn't as smooth as I remember-- maybe I'm thinking of someone else?

Anyway, the cold piping is well done, but the transition to the top charger isn't as good as it could be.

See how the pipe flares out as it goes into the (edit: SMALL) turbo? This is what needs to be done, but done better. The transition here is too abrupt. The transition angle here is probably more than 30º. You want this angle as low as possible.(edit: not)

EDIT: You don't really want the angle as small as possible-- this is wrong info. The angle for a diffuser should be as high as you can get WITHOUT getting separation of the flow. So the optimum diffuser angle is a function of flow velocity-- the faster the velocity, the less angle can be used before separation sets in.

If they had started the transition back before the visible weld bead, you'd have a much more gradual angle that would reduce or eliminate flow separation which increases drag in the conduit and leads to small eddy currents forming at the transition point.

I'll see if i can find the pic of the "right" twins I'm thinking of.

#200

I think the MPI twins have the cleanest transition that I have seen????

So I am thinking about building my own set up...probably just going do a S400/stock turbo set-up..like the MPI's...the way I am looking at it now this seems to be the most cost effective set-up until I am ready to build two custom turbos.

questions... is Rip source the best or only place to get parts??? their site does not really list any 3rd gen stuff.. or do the HX35 and HX40 parts fit on the 3gen turbos?? I guess I could make my own flanges..but if they are as cheap as the ones at rip's then I may just go that route....

also can a guy just get a 2nd gen exhaust manifold and use it or should I just get the BD or ATS or other????

So I am thinking about building my own set up...probably just going do a S400/stock turbo set-up..like the MPI's...the way I am looking at it now this seems to be the most cost effective set-up until I am ready to build two custom turbos.

questions... is Rip source the best or only place to get parts??? their site does not really list any 3rd gen stuff.. or do the HX35 and HX40 parts fit on the 3gen turbos?? I guess I could make my own flanges..but if they are as cheap as the ones at rip's then I may just go that route....

also can a guy just get a 2nd gen exhaust manifold and use it or should I just get the BD or ATS or other????

#201

DTR 1st Sergeant

Thread Starter

There have been talk back and forth that the larger coldpipes make for some lag but I havent seen any proof either way. I think the smaller coldpipes are used for ease of installation. I run a 4" coldpipe and it was tight, I dont know how soulezoo got his in there. Just my $0.02

My cold pipe is an even 4" all the way.

#202

Registered User

Join Date: Apr 2003

Location: Cummins Technical Center, IN

Posts: 6,564

Likes: 0

Received 6 Likes

on

5 Posts

The expansion to 4" right away will slow down the flow and cool it a little bit.

The larger pipe will do a better job handling the large 180º U-bend that feeds the small charger, because the restriction caused by a bend in the pipe is closely related to the velocity of the flow in that pipe. If you have really slow-moving gases in a pipe, then the bends in it become less and less restrictive proportionally.

But the flow will likely experience more shearing, which is not good. This is simply because the air traveling around the inside of the bend has much less distance to travel than the flow going around the outside of the bend. Because of the path length differences, you will have shearing in the flow and an increase in restriction.

To prevent shearing but preserve flow capacity, you'd want to re-shape the big 180º bend that feeds the secondary. Instead of having a round pipe making the bend, it would be much better to have a flattened, wide conduit making the bend. Imagine like a "cobra's hood" sort of treatment where the pipe is flattened but expanded out, thus preserving cross-sectional area.

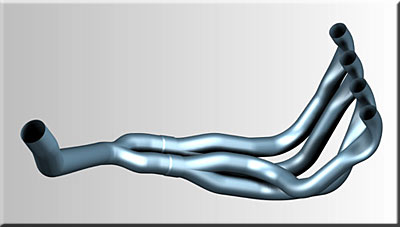

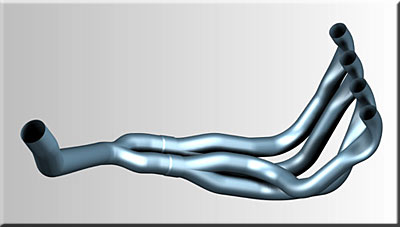

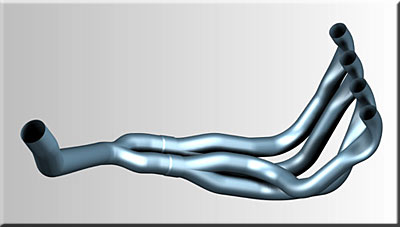

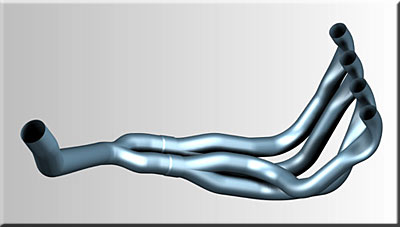

Look at this motorcycle exhaust from Micron:

See how the pipe is shaped just as it comes out of the cylinders? THIS is what I'm talking about. A change to the shape of the conduit can preserve velocity through a bend while drastically reducing shearing.

Because of shearing effects and the "pooling" of the flow in the outside of a large crosspipe, I'd GUESS that the larger cold pile will perform the poorest.

This is something I'd love to test-- whether the increased shearing of the larger pipe is offset by the reduction in velocity or not.

Assuming I can find someone that can do the ultra-trick tube bends I'm trying to find (like the motorcycle pipes above), the plumbing for MY twins will be most unconventional in appearance!

Justin

The larger pipe will do a better job handling the large 180º U-bend that feeds the small charger, because the restriction caused by a bend in the pipe is closely related to the velocity of the flow in that pipe. If you have really slow-moving gases in a pipe, then the bends in it become less and less restrictive proportionally.

But the flow will likely experience more shearing, which is not good. This is simply because the air traveling around the inside of the bend has much less distance to travel than the flow going around the outside of the bend. Because of the path length differences, you will have shearing in the flow and an increase in restriction.

To prevent shearing but preserve flow capacity, you'd want to re-shape the big 180º bend that feeds the secondary. Instead of having a round pipe making the bend, it would be much better to have a flattened, wide conduit making the bend. Imagine like a "cobra's hood" sort of treatment where the pipe is flattened but expanded out, thus preserving cross-sectional area.

Look at this motorcycle exhaust from Micron:

See how the pipe is shaped just as it comes out of the cylinders? THIS is what I'm talking about. A change to the shape of the conduit can preserve velocity through a bend while drastically reducing shearing.

Because of shearing effects and the "pooling" of the flow in the outside of a large crosspipe, I'd GUESS that the larger cold pile will perform the poorest.

This is something I'd love to test-- whether the increased shearing of the larger pipe is offset by the reduction in velocity or not.

Assuming I can find someone that can do the ultra-trick tube bends I'm trying to find (like the motorcycle pipes above), the plumbing for MY twins will be most unconventional in appearance!

Justin

#203

DTR 1st Sergeant

Thread Starter

I think the MPI twins have the cleanest transition that I have seen????

So I am thinking about building my own set up...probably just going do a S400/stock turbo set-up..like the MPI's...the way I am looking at it now this seems to be the most cost effective set-up until I am ready to build two custom turbos.

questions... is Rip source the best or only place to get parts??? their site does not really list any 3rd gen stuff.. or do the HX35 and HX40 parts fit on the 3gen turbos?? I guess I could make my own flanges..but if they are as cheap as the ones at rip's then I may just go that route....

also can a guy just get a 2nd gen exhaust manifold and use it or should I just get the BD or ATS or other????

So I am thinking about building my own set up...probably just going do a S400/stock turbo set-up..like the MPI's...the way I am looking at it now this seems to be the most cost effective set-up until I am ready to build two custom turbos.

questions... is Rip source the best or only place to get parts??? their site does not really list any 3rd gen stuff.. or do the HX35 and HX40 parts fit on the 3gen turbos?? I guess I could make my own flanges..but if they are as cheap as the ones at rip's then I may just go that route....

also can a guy just get a 2nd gen exhaust manifold and use it or should I just get the BD or ATS or other????

#204

DTR 1st Sergeant

Thread Starter

The expansion to 4" right away will slow down the flow and cool it a little bit.

The larger pipe will do a better job handling the large 180º U-bend that feeds the small charger, because the restriction caused by a bend in the pipe is closely related to the velocity of the flow in that pipe. If you have really slow-moving gases in a pipe, then the bends in it become less and less restrictive proportionally.

But the flow will likely experience more shearing, which is not good. This is simply because the air traveling around the inside of the bend has much less distance to travel than the flow going around the outside of the bend. Because of the path length differences, you will have shearing in the flow and an increase in restriction.

To prevent shearing but preserve flow capacity, you'd want to re-shape the big 180º bend that feeds the secondary. Instead of having a round pipe making the bend, it would be much better to have a flattened, wide conduit making the bend. Imagine like a "cobra's hood" sort of treatment where the pipe is flattened but expanded out, thus preserving cross-sectional area.

Look at this motorcycle exhaust from Micron:

See how the pipe is shaped just as it comes out of the cylinders? THIS is what I'm talking about. A change to the shape of the conduit can preserve velocity through a bend while drastically reducing shearing.

Because of shearing effects and the "pooling" of the flow in the outside of a large crosspipe, I'd GUESS that the larger cold pile will perform the poorest.

This is something I'd love to test-- whether the increased shearing of the larger pipe is offset by the reduction in velocity or not.

Assuming I can find someone that can do the ultra-trick tube bends I'm trying to find (like the motorcycle pipes above), the plumbing for MY twins will be most unconventional in appearance!

Justin

The larger pipe will do a better job handling the large 180º U-bend that feeds the small charger, because the restriction caused by a bend in the pipe is closely related to the velocity of the flow in that pipe. If you have really slow-moving gases in a pipe, then the bends in it become less and less restrictive proportionally.

But the flow will likely experience more shearing, which is not good. This is simply because the air traveling around the inside of the bend has much less distance to travel than the flow going around the outside of the bend. Because of the path length differences, you will have shearing in the flow and an increase in restriction.

To prevent shearing but preserve flow capacity, you'd want to re-shape the big 180º bend that feeds the secondary. Instead of having a round pipe making the bend, it would be much better to have a flattened, wide conduit making the bend. Imagine like a "cobra's hood" sort of treatment where the pipe is flattened but expanded out, thus preserving cross-sectional area.

Look at this motorcycle exhaust from Micron:

See how the pipe is shaped just as it comes out of the cylinders? THIS is what I'm talking about. A change to the shape of the conduit can preserve velocity through a bend while drastically reducing shearing.

Because of shearing effects and the "pooling" of the flow in the outside of a large crosspipe, I'd GUESS that the larger cold pile will perform the poorest.

This is something I'd love to test-- whether the increased shearing of the larger pipe is offset by the reduction in velocity or not.

Assuming I can find someone that can do the ultra-trick tube bends I'm trying to find (like the motorcycle pipes above), the plumbing for MY twins will be most unconventional in appearance!

Justin

Now that's just great... another thing to worry about on these durn

things

Seriously-- Justin thank you for your insight. The knowledge is invaluable.

#205

Man flat bends like the exhaust above is easy!!! buy a harbor freight pipe bender....it will make flat bends all day long

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

#206

Banned

Join Date: Dec 2005

Location: Twin Falls, Idaho

Posts: 5,194

Likes: 0

Received 0 Likes

on

0 Posts

Man flat bends like the exhaust above is easy!!! buy a harbor freight pipe bender....it will make flat bends all day long

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

Harbor freight... THat's funny dude... Hey Just grab the ms. and the kids and come up for the weekend and you can take pic's and measurements if you want... If not call me I'll help you out... I think rip is the only real place to get the parts you need!!!

#207

But then I would have to tell Rachel the "new" plan

#208

Banned

Join Date: Dec 2005

Location: Twin Falls, Idaho

Posts: 5,194

Likes: 0

Received 0 Likes

on

0 Posts

#209

Registered User

Join Date: May 2007

Location: Kalispell Montana

Posts: 349

Likes: 0

Received 0 Likes

on

0 Posts

I dont know what he has but Piers Harry has a shop again.

http://www.peakdieselperformance.com...ge/4863099.htm

http://www.peakdieselperformance.com...ge/4863099.htm

#210

Man flat bends like the exhaust above is easy!!! buy a harbor freight pipe bender....it will make flat bends all day long

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

finding a shop to bend stuff like that is $$$$ I will be excited to see your set-up Justin..it sounds like it is going to be pretty pimp

I will just be using regular mandrel bends...

so are there any other "parts" people who sell twins parts??

I think Nathan is supplying "aftermarket" manifolds now?? but dang I can get a 2nd gen manifold for $25 bucks...that's hard to beat IMHO if it works????

If you're talking about using a stock 2nd gen manifold, I'm not sure a stocker can handle the extra weight of the twins?