P pump fuel pressure help

#1

Registered User

Thread Starter

Join Date: Jul 2019

Location: Texas

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

P pump fuel pressure help

I'm new to the diesel scene and am needing a little help. I have tried to talk to different shops but of course they don't want to tell me anything they want me to bring them my truck so they can charge me. I have a 01 3500 5.9 with the p pump. It had this and some other mods when I bought it. I recently put a field sump in it and when I was ready to fire it up I cracked the lines at the p pump. Bumped the ignition so the lift pump would ingage so I could bleed the air out. I noticed that 2 of the lines had fuel pouring out and the other didn't. What does this mean? Are my injectors going out or already out? Any help would be mighty appreciated.

#2

Registered User

While I am not very familiar with the P7100 pump as my 01 used the oem VP44, when I bled my lines in the past I would do one at a time at the head. Once they had fuel coming out I would tighten it up and then do the next one. I dont ever remember having to do more than 3 before the truck would start. Bad injectors should not keep a P7100 or VP44 from sending fuel through the lines that I am aware. Each injector has its own line from the pump to the injector. Also unless I misread your post I think you will need to crack the injector lines at the head to get the air out of the lines between the pump and the injector. Injectors in the 01 are not smart if they have the proper pressure to open them fuel will flow through them it may come at the wrong pressure or amount but fuel will still flow unless they are clogged and not sure I have ever heard of that before. I assume the truck was running before you put the sump in.

#3

Registered User

Thread Starter

Join Date: Jul 2019

Location: Texas

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

I cracked them at the head also and same result a couple of the lines had fuel pouring out and the others not so much. I have pulled the full lines off and blew them out just to make sure they were clean. Just wanting to know why the difference in pressure

#4

Registered User

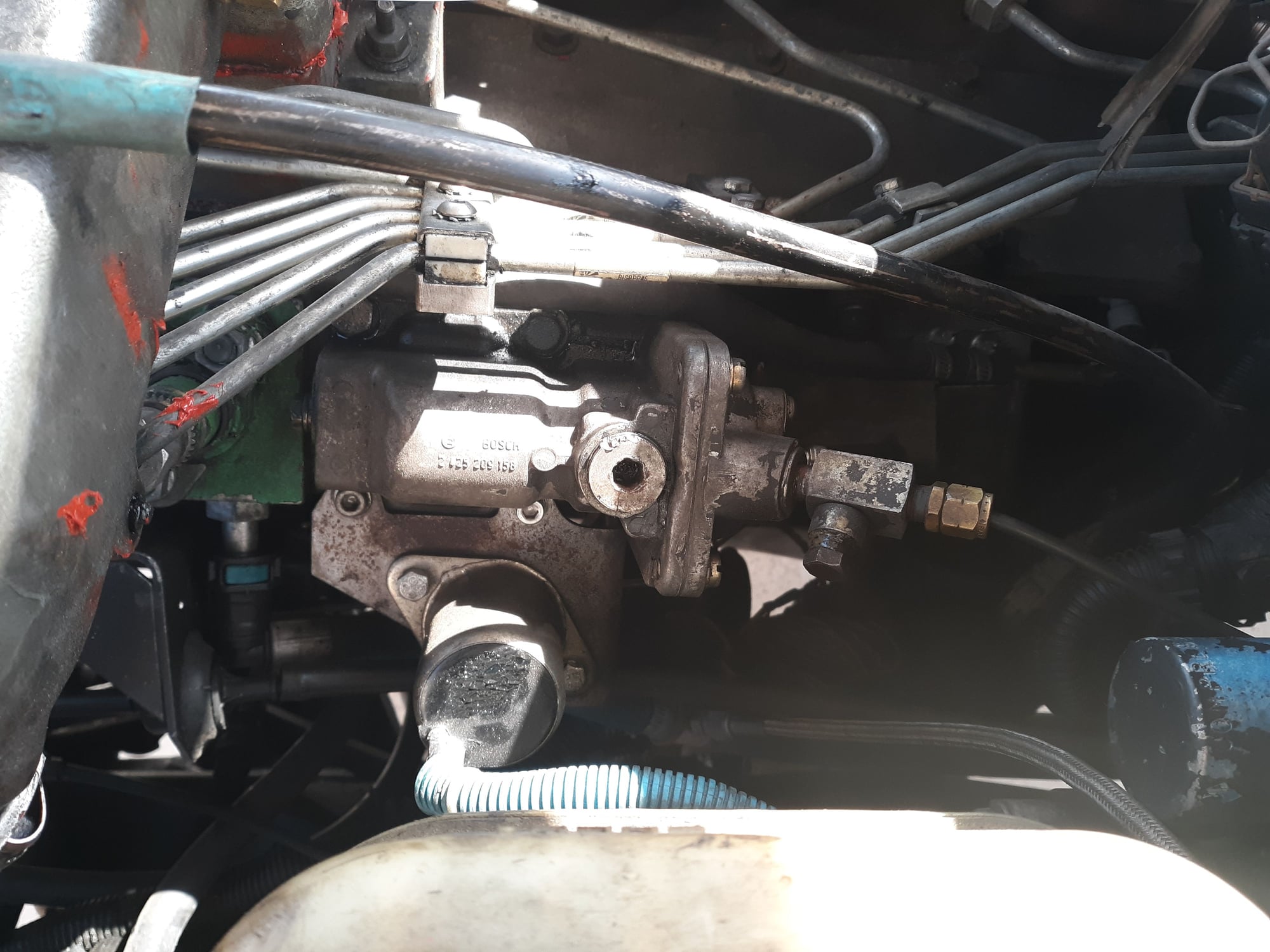

Could you take a pic of your pump and post it?

Here, if discussing fuel pressure we actually mean the supply pressure going into the injection pump, not the injection pressure.

For any injection pump the visual inspection of the flow from an open end will be inconclusive. You would need to put on a set of injectors and then measure the fuel quantity after 1000 revolutions. This should be very close to equal for each injector, and should correspond to some value in a table with test results for your pump.

Here, if discussing fuel pressure we actually mean the supply pressure going into the injection pump, not the injection pressure.

For any injection pump the visual inspection of the flow from an open end will be inconclusive. You would need to put on a set of injectors and then measure the fuel quantity after 1000 revolutions. This should be very close to equal for each injector, and should correspond to some value in a table with test results for your pump.

#6

Registered User

OK, with the P-Pump it's like that- if you feed it fuel under sufficient pressure while it is standing still you will observe fuel coming from some delivery valves but not all of them- this is normal.

It is caused by the fact that only pump pistons that are in a position to open the cutoff will let fuel through in that case.

Normally the piston lifts and pressurizes fuel until it reaches the cutoff position of the barrel, where fuel is bled off into the feed chamber.

To bleed the air out of the P-Pumps you need to first get the pump full of fuel, then open at least 3 injector lines at the head and crank the engine for some seconds until clean and bubble free fuel comes out- tighten the lines again and try to start the engine. If it fires and runs rough you can open and close more injection lines at the head to bleed air out of the other lines, or simply let the engine run for some time it will purge the air, especially if you put some load on it- but it will take time.

It is caused by the fact that only pump pistons that are in a position to open the cutoff will let fuel through in that case.

Normally the piston lifts and pressurizes fuel until it reaches the cutoff position of the barrel, where fuel is bled off into the feed chamber.

To bleed the air out of the P-Pumps you need to first get the pump full of fuel, then open at least 3 injector lines at the head and crank the engine for some seconds until clean and bubble free fuel comes out- tighten the lines again and try to start the engine. If it fires and runs rough you can open and close more injection lines at the head to bleed air out of the other lines, or simply let the engine run for some time it will purge the air, especially if you put some load on it- but it will take time.

#7

Registered User

Thread Starter

Join Date: Jul 2019

Location: Texas

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

Ok thanks for explaining that. I have another question. My afc has no foot or a fuel plate so if I adjust the star wheel or the smoke screw will it have any effect on anything

Trending Topics

#8

Registered User

Without a foot the AFC does nothing, without a fuel plate you are in quite dangerous territory in my opinion.

(It's very easy to overfuel massively and damage the engine- I hope you have an EGT gauge!)

A little longer if you care to read:

Both the AFC and the fuel plate do limit the maximum amount of fuel that can be injected per power stroke, depending on engine RPM.

The AFC is a fuel plate that gets moved out of the way if there is boost.

The reasoning behind this limiting of max fuel is twofold- A keeping the engine alive and B the environment.

A diesel engine can burn one unit of mass od diesel with about 22 units of mass of air in the cylinder without smoking.

If you have less than 22 times the mass of air for your fuel things start to get very hot very quickly, and pistons look like lollypops.

So, the plate limits the amount of fuel at full boost, and it has a contour to adjust the max for engine rpm. This is needed because the cam is not always optimal, so the amount of air in the cylinder varies over rpm.

With only a plate there is no limiting of low boost fuel, and the change between trying to fill the cylinder with 14.7 psi of atmospheric pressure and filling it with air that is at 35 psi of boost (coming to a total of 49.4 psi) is evident.

With some time and knowledge you can adjust a P-Pump to give you snappy acceleration without undue smoke, and EGTs that stay sane by simply stepping on the loud pedal.

Without AFC and plate you have to do all this yourself.

And if your truck has an automatic transmission you can not keep it in lower gear by stepping on the loud pedal without risking a viking funeral for your pistons and exhaust valves.

I do not see a benefit in removing the plate and AFC, especially for an on road vehicle.

Max fuel is limited by the rack plug, the injectors and the delivery valves.

Max power is usually limited by the amount of air you can cram in there, and the stability of the engine (read the P-Pump with big DVs and big injectors can deliver enough fuel that given enough air you can crack the block... even with a girdle and head studs.. north of 1000 hp.. should be enough, and is achievable with a plate and an AFC. )

(It's very easy to overfuel massively and damage the engine- I hope you have an EGT gauge!)

A little longer if you care to read:

Both the AFC and the fuel plate do limit the maximum amount of fuel that can be injected per power stroke, depending on engine RPM.

The AFC is a fuel plate that gets moved out of the way if there is boost.

The reasoning behind this limiting of max fuel is twofold- A keeping the engine alive and B the environment.

A diesel engine can burn one unit of mass od diesel with about 22 units of mass of air in the cylinder without smoking.

If you have less than 22 times the mass of air for your fuel things start to get very hot very quickly, and pistons look like lollypops.

So, the plate limits the amount of fuel at full boost, and it has a contour to adjust the max for engine rpm. This is needed because the cam is not always optimal, so the amount of air in the cylinder varies over rpm.

With only a plate there is no limiting of low boost fuel, and the change between trying to fill the cylinder with 14.7 psi of atmospheric pressure and filling it with air that is at 35 psi of boost (coming to a total of 49.4 psi) is evident.

With some time and knowledge you can adjust a P-Pump to give you snappy acceleration without undue smoke, and EGTs that stay sane by simply stepping on the loud pedal.

Without AFC and plate you have to do all this yourself.

And if your truck has an automatic transmission you can not keep it in lower gear by stepping on the loud pedal without risking a viking funeral for your pistons and exhaust valves.

I do not see a benefit in removing the plate and AFC, especially for an on road vehicle.

Max fuel is limited by the rack plug, the injectors and the delivery valves.

Max power is usually limited by the amount of air you can cram in there, and the stability of the engine (read the P-Pump with big DVs and big injectors can deliver enough fuel that given enough air you can crack the block... even with a girdle and head studs.. north of 1000 hp.. should be enough, and is achievable with a plate and an AFC. )

#9

Registered User

Thread Starter

Join Date: Jul 2019

Location: Texas

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

The fuel plate and foot were already removed when I got the truck. I use the truck for work it's my rig truck. It has around 2000 lbs added to it. So not having the foot that big of a deal but I need to put a fuel plate back on it. Once I do that it will reduce the smoke or do I need the foot also. I dont need a race truck although I do like the ability to be able to get around others when needed. Thanks for help

#10

Registered User

I'd get both- the truck will have much better driveability after you sorted them out.

You did not say if auto or manual- if auto a working AFC is necessary to get good shifting at less than WOT.

You seem to have some Crazy Karls parts on there- maybe we should try to identify what you have on the air side, and maybe also a pic of the head with the valve cover off to determine if you have studs...

A P-Pump on the 24 V can mean 2 things- either someone got fed up with VP44s dying like mayflies, or someone could not wring enough fuel out of the VP44.. (sixhundredplus hp not enough??)

Anyways, regardless of what the truck was built for, I'd suggest you make it your own now by adapting it to your needs.

You did not say if auto or manual- if auto a working AFC is necessary to get good shifting at less than WOT.

You seem to have some Crazy Karls parts on there- maybe we should try to identify what you have on the air side, and maybe also a pic of the head with the valve cover off to determine if you have studs...

A P-Pump on the 24 V can mean 2 things- either someone got fed up with VP44s dying like mayflies, or someone could not wring enough fuel out of the VP44.. (sixhundredplus hp not enough??)

Anyways, regardless of what the truck was built for, I'd suggest you make it your own now by adapting it to your needs.

#11

Registered User

Thread Starter

Join Date: Jul 2019

Location: Texas

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

It's a 5 speed. I know it has Carl's turo internals. It has a 188/220 cam, 4k gov springs, full cut delivery valve, apr head studs, raptor 150 lift pump, 215p pump, .93 injection lines, 150hp injector nozzles, fuel sump, one piece drive shaft, nv4500 transmission that I had built for it with biger input shaft and cryogenic gears. That's everything that I know that has been done to it. I few months back it had jumped timing well the timing gear slipped due to not being torqued properly. I had a shop fix it and I know they set it back to stock timing they didn't advance it for the cam.

Thread

Thread Starter

Forum

Replies

Last Post

dodgeguy71

Performance and Accessories 2nd gen only

17

01-19-2012 12:52 AM

MoparRiggan

3rd Gen High Performance and Accessories (5.9L Only)

7

01-05-2006 11:09 AM