Running US Gear D-Celerator exhaust brake with only a relay and switch

#1

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

Running US Gear D-Celerator exhaust brake with only a relay and switch

Hopefully the title defines the challenge adequately. I've had for 10 plus years on a dusty shelf a US Gear D-Celerator inline (non-turbo mounted) exhaust brake. It's the electric actuated model with a 2370es dual coil solenoid actuator. Unfortunately I don't have any of the control electronics, only the cast iron butterfly body with the solenoid mounted on it along with the clamps to secure to the exhaust pipe.

Since the solenoid slams the valve closed when 12 volts is applied I'm thinking I can use this, the question is exactly how ? Online research indicates the solenoid draws almost 60 amps so a 60 to 80 amp relay would be needed? Would 2 be required, one to open the other to close or could one relay do the job?

My simple mind thinks an appropriate shifter mounted rocker switch (perhaps, button may be better ?) that I could engage on big hills and with a finger tap disengage at the bottom. But, how to wire it????????

Any help on wiring and any other suggestions will be greatly appreciated.

Since the solenoid slams the valve closed when 12 volts is applied I'm thinking I can use this, the question is exactly how ? Online research indicates the solenoid draws almost 60 amps so a 60 to 80 amp relay would be needed? Would 2 be required, one to open the other to close or could one relay do the job?

My simple mind thinks an appropriate shifter mounted rocker switch (perhaps, button may be better ?) that I could engage on big hills and with a finger tap disengage at the bottom. But, how to wire it????????

Any help on wiring and any other suggestions will be greatly appreciated.

#2

Registered User

As for the relay- use a starter relay from an old Jeep or the like. (From the times when there was a relay on the fender)

There are some 80A relays on Amazon too, they should be less than 10US$/pc.

If the solenoid has only one contact the brake should reset itself when there is no power to the solenoid.

Now for some logic- Wire like this: from battery to a fuse to the switched side and then to the solenoid.

Then from an ignition on power source through an idle validation switch* to a shifter mounted switch or button, then to the coil side of the relay. The other side of the relay coil goes to ground.

* Idle validation switch- mount a momentary switch to the bracket where the throttle cable goes, so that there is a contact only with the pedal at idle. (you could also use a reed switch)

If you want it to be completely nifty, you could also use the brake light voltage to supply the relay, instead of going from an ignition on power source.

That way the EB would come on if you had A: the throttle at idle B: the switch at the shifter set to active and C: the brake lights lit

(You would get used to "ride the brakes" down the hill without actually braking)

It is necessary to assure that there is not more than idle fuel with the EB active if you want to keep your engine happy. Therefore with the idle validation switch the EB will open the moment you step on the skinny pedal.

If it's for the 95 you should consider stronger springs for the exhaust valves, the stock springs were too soft for this.

HTH

There are some 80A relays on Amazon too, they should be less than 10US$/pc.

If the solenoid has only one contact the brake should reset itself when there is no power to the solenoid.

Now for some logic- Wire like this: from battery to a fuse to the switched side and then to the solenoid.

Then from an ignition on power source through an idle validation switch* to a shifter mounted switch or button, then to the coil side of the relay. The other side of the relay coil goes to ground.

* Idle validation switch- mount a momentary switch to the bracket where the throttle cable goes, so that there is a contact only with the pedal at idle. (you could also use a reed switch)

If you want it to be completely nifty, you could also use the brake light voltage to supply the relay, instead of going from an ignition on power source.

That way the EB would come on if you had A: the throttle at idle B: the switch at the shifter set to active and C: the brake lights lit

(You would get used to "ride the brakes" down the hill without actually braking)

It is necessary to assure that there is not more than idle fuel with the EB active if you want to keep your engine happy. Therefore with the idle validation switch the EB will open the moment you step on the skinny pedal.

If it's for the 95 you should consider stronger springs for the exhaust valves, the stock springs were too soft for this.

HTH

#3

Registered User

Another way would be to copy the design of Euro OTR trucks, where the EB is operated by a foot switch that is on the left front of the driver's seat.

That way you have to pull your left foot back from the clutch pedal and rest the heel on the switch for going downhill.

I always found this to be quite comfortable.

On the said trucks, the EB would also put the IP to zero diesel injected, and you would shut down the engine by pushing the switch while in Neutral.

Anyways, it is very important to make sure that not a lot of diesel can be injected while the EB is on.

(IMO it would be preferable to get to zero output on the IP while the EB is on- maybe tie in the shutdown solenoid in some way.)

That way you have to pull your left foot back from the clutch pedal and rest the heel on the switch for going downhill.

I always found this to be quite comfortable.

On the said trucks, the EB would also put the IP to zero diesel injected, and you would shut down the engine by pushing the switch while in Neutral.

Anyways, it is very important to make sure that not a lot of diesel can be injected while the EB is on.

(IMO it would be preferable to get to zero output on the IP while the EB is on- maybe tie in the shutdown solenoid in some way.)

#4

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

HTH, Thanks! You've provided exactly the type help I was hoping to get. I particularly like the foot operated switch. I've got a full life load for the next few weeks (baling hay then a two week trip to Malaysia) so, it'll be a while till I can get back on this page.

And yes this is for the 95. Bought it new, added 60lb. exhaust springs last year. At 66 years of age, I've decided I won't be able to wear the old truck out in this lifetime.

I hope to have a detailed plan and all parts on hand at the end of September so I can quickly do the install prior to a hunting trip pulling our 11k hunting trailer though the Colorado Rockies.

I "May" be back with specific detailed questions in the near future.

Thanks Again!!!

RonR

And yes this is for the 95. Bought it new, added 60lb. exhaust springs last year. At 66 years of age, I've decided I won't be able to wear the old truck out in this lifetime.

I hope to have a detailed plan and all parts on hand at the end of September so I can quickly do the install prior to a hunting trip pulling our 11k hunting trailer though the Colorado Rockies.

I "May" be back with specific detailed questions in the near future.

Thanks Again!!!

RonR

#5

Registered User

Stay safe while baling and have a nice trip!

Just respond to this thread when you are back, maybe I'll have something like wiring plans for that thing for you :-)

Just respond to this thread when you are back, maybe I'll have something like wiring plans for that thing for you :-)

#6

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Alpine! Hay's all done and in the barn. Leave tomorrow for Asia. When we return on the 18th it's a full on battle to get ready for the annual Colorado hunt/trip.

Looking forward to an exhaust brake this year.

RonR

Looking forward to an exhaust brake this year.

RonR

#7

Registered User

Good to hear, hope you'll enjoy the trip.

I'll look into something to make the stock shutdown solenoid into something that can operate with the EB.

(Problem is that it needs to apply pull up power for a short time after releasing the EB, hold needs to be cut off while EB is active etc)

I'll look into something to make the stock shutdown solenoid into something that can operate with the EB.

(Problem is that it needs to apply pull up power for a short time after releasing the EB, hold needs to be cut off while EB is active etc)

Trending Topics

#8

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

Made it back incountry after a grueling 27 hours (air and airport time). Now to get back on the truck repairs/upgrades as the Colorado trip looms in the windshield.

Alpine Ram, any further thoughts on a (simple) activation system? Hopefully the attached images help. The last image shows all the items I don't have for a factory correct installation.

In rereading the suggestions above you mention an idle validation switch. Great idea, however I'm very OK and actually prefer the KISS method. Keeping it simple so that I manually actuate a switch, engaging the brake when going down a hill and then de-activating it at the bottom.

A couple closing points, the normal position of the brake's butterfly is open. Power closes, remove power and it snaps open. It's been suggested that the brake solenoid has two pull coils just like the fuel shutoff solenoid does. One will draw a lot more than the other which begs the question, how to wire to allow it to work properly if that's the case.

OH, and thanks again!

Alpine Ram, any further thoughts on a (simple) activation system? Hopefully the attached images help. The last image shows all the items I don't have for a factory correct installation.

In rereading the suggestions above you mention an idle validation switch. Great idea, however I'm very OK and actually prefer the KISS method. Keeping it simple so that I manually actuate a switch, engaging the brake when going down a hill and then de-activating it at the bottom.

A couple closing points, the normal position of the brake's butterfly is open. Power closes, remove power and it snaps open. It's been suggested that the brake solenoid has two pull coils just like the fuel shutoff solenoid does. One will draw a lot more than the other which begs the question, how to wire to allow it to work properly if that's the case.

OH, and thanks again!

#9

Registered User

Yep, this is the same solenoid as in the shutdown solenoid of the P-Pump 12V trucks.

It works like that- power to the hold cable energizes a coil that has enough power to hold the plunger up, but not to pull it up. Power to the pull up cable pulls up the plunger. For the IP this is done by activating the hold coil via the ignition switch and the pull up by the starter.

You must not keep the pull up coil energised for too long, it will overheat. (And it can burn your truck to the ground..)

Please check the following: Put ground to the black wire, +12V to the white wire- the flapper should not close.

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)

Maybe the holding coil has enough power to close the EB on it's own when there is no exhaust pressure.. but basically the holding coil uses much less power and has a much higher resistance than the pull up coil)

In your documentation you see a defeat switch- this is what I called the idle validation switch. Even a little bit of diesel injected with the brake active can kill your engine in seconds.

(And even with the accelerator not pressed the IP will start to fuel when you get close to curb idle rpm)

Nevertheless- you need at least 3 relays and a switch. (Like the foot switch suggested.)

A simple relay to apply power to the hold coil as long as the switch is applied

A timer relay that will apply a short pulse to the pull coil when you activate. Something like

http://www.produktinfo.conrad.com/da...ELAIS_12_V.pdf

See page 3 Scheme GI "Pulse delayed" - T needs to be set quite short (1/4 second)

Naturally you will need an amplification relay after the timer, the timer can only switch 10A, you need 60A.

LarryB has good stuff, and you have a spare for when the stock relay for controlling the IP fails

It works like that- power to the hold cable energizes a coil that has enough power to hold the plunger up, but not to pull it up. Power to the pull up cable pulls up the plunger. For the IP this is done by activating the hold coil via the ignition switch and the pull up by the starter.

You must not keep the pull up coil energised for too long, it will overheat. (And it can burn your truck to the ground..)

Please check the following: Put ground to the black wire, +12V to the white wire- the flapper should not close.

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)

Maybe the holding coil has enough power to close the EB on it's own when there is no exhaust pressure.. but basically the holding coil uses much less power and has a much higher resistance than the pull up coil)

In your documentation you see a defeat switch- this is what I called the idle validation switch. Even a little bit of diesel injected with the brake active can kill your engine in seconds.

(And even with the accelerator not pressed the IP will start to fuel when you get close to curb idle rpm)

Nevertheless- you need at least 3 relays and a switch. (Like the foot switch suggested.)

A simple relay to apply power to the hold coil as long as the switch is applied

A timer relay that will apply a short pulse to the pull coil when you activate. Something like

http://www.produktinfo.conrad.com/da...ELAIS_12_V.pdf

See page 3 Scheme GI "Pulse delayed" - T needs to be set quite short (1/4 second)

Naturally you will need an amplification relay after the timer, the timer can only switch 10A, you need 60A.

LarryB has good stuff, and you have a spare for when the stock relay for controlling the IP fails

#10

Registered User

But, a better version in my opinion would be like that:

The brake hold relay turning off the hold power for the shutdown solenoid (using the NC contact of the relay) when turning on the power for the brake hold solenoid on it's NO contact.

Like that you make sure that the IP gives you no fuel while the brake is active.

The downside is that you need another timer relay and associated amplifier relay to send a pulse to the pull coil of the shutdown solenoid when you release the brake.

Add in some fancy LEDs to see what your brake is doing, (One LED per coil, so if you do the option with the shutdown solenoid you'll have 4 LEDs)

The brake hold relay turning off the hold power for the shutdown solenoid (using the NC contact of the relay) when turning on the power for the brake hold solenoid on it's NO contact.

Like that you make sure that the IP gives you no fuel while the brake is active.

The downside is that you need another timer relay and associated amplifier relay to send a pulse to the pull coil of the shutdown solenoid when you release the brake.

Add in some fancy LEDs to see what your brake is doing, (One LED per coil, so if you do the option with the shutdown solenoid you'll have 4 LEDs)

#11

Registered User

I found something interesting..

With 2 relays and a capacitor and 2 diodes plus one switch we can do everything that the controller that you lack does, but better.

Should be rather cheap and simple, and allow you to use the EB under 1500rpm with very low bypass, meaning very efficiently.

An additional switch and you have a quick warmup feature too.

With 2 relays and a capacitor and 2 diodes plus one switch we can do everything that the controller that you lack does, but better.

Should be rather cheap and simple, and allow you to use the EB under 1500rpm with very low bypass, meaning very efficiently.

An additional switch and you have a quick warmup feature too.

#12

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

"Please check the following: Put ground to the black wire, +12V to the white wire- the flapper should not close.

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)"

The above I'll do in the morning.

"With 2 relays and a capacitor and 2 diodes plus one switch we can do everything that the controller that you lack does, but better."

What a tease!! Sounds like a great and simple possibility. Did I mention I'm fairly electron challenged? The good news is I have a brother I'll try to recruit who is quite comfortable with the devils invention (electricity).

RR

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)"

The above I'll do in the morning.

"With 2 relays and a capacitor and 2 diodes plus one switch we can do everything that the controller that you lack does, but better."

What a tease!! Sounds like a great and simple possibility. Did I mention I'm fairly electron challenged? The good news is I have a brother I'll try to recruit who is quite comfortable with the devils invention (electricity).

RR

#13

Registered User

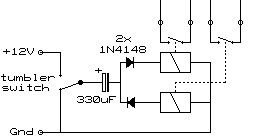

A simple scheme to get two different pulses out of a state change switch. Usable for an engine brake controller

With that scheme you need an EB switch that has 2 sets of contacts, one for pressed one for not pressed (in other words a switch with one NC and one NO contact)

On each change of position in the tumbler switch (or your other kind of switch) the relay you switched to is active for about 0.2 seconds.

(This is for a 12V relay with about 260 ohms of coil resistance)

So, with that switch controlling power to the solenoids for holding the function (IP run and EB) it will activate the pull up coil on each function for a short time to get the desired result.

Naturally these small relays are used to control some beefy 60A relays to make that stuff durable.

To avoid troubles with the starter ticking everytime you deactivate the EB you will need to install a diode that isolates the pull up solenoid of the IP from the starter.

I think like that you can adjust the exhaust brake to a quite high pressure without getting to melted piston land, and you can even stop the engine by applying the EB.

Clear as mud?

#14

Registered User

Thread Starter

Join Date: Dec 2001

Location: Arkansas woods

Posts: 229

Likes: 0

Received 0 Likes

on

0 Posts

"Please check the following: Put ground to the black wire, +12V to the white wire- the flapper should not close.

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)"

Lots going on and I just got back to this project today. I did do the above with these results:

Red is hold open, white is shut. And man does it close, one would likely loose a finger is it happened to be in the wrong place at the right time!

Then apply +12v momentarily to the red wire, flapper should slam shut and stay there until you open the white wire connection. (Or it is the other way round, red to hold and white to shut)"

Lots going on and I just got back to this project today. I did do the above with these results:

Red is hold open, white is shut. And man does it close, one would likely loose a finger is it happened to be in the wrong place at the right time!

#15

Registered User

OK, now with the circuit I showed, connect the holding circuits with a relay.

On the NC contact the shutdown solenoid, on the NO the exhaust brake.

The shown diagram goes to the " slam shut (white)" on the EB side and the "start (whatever color)" on the shutdown solenoid side.

On the NC contact the shutdown solenoid, on the NO the exhaust brake.

The shown diagram goes to the " slam shut (white)" on the EB side and the "start (whatever color)" on the shutdown solenoid side.

Thread

Thread Starter

Forum

Replies

Last Post

ddestruel

Performance and Accessories 2nd gen only

4

04-19-2005 01:00 PM