My new 32x48 1st Gen Storage Facility.... ;)

#106

Registered User

Yes I have a metal roof so when it slides it can be exciting.

Your shingled roof will be a different beast...good point.

Your shingled roof will be a different beast...good point.

#107

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,769

Received 1,637 Likes

on

1,112 Posts

Time for another update.

Got the lower 9 feet wrapped with help from coffeeaddict...

Picked up the first large order for the electrical and have started to lay out receptical box's and lighting locations and run a bit of wire.

Then had a bunch of custom 26 ga tin bent up for the shop, lower trim in black to cover the ridgid insulation on the foundation, trim around the garage doors is in white, and one last area in black to cover the facia boards and also extend down a bit to allow the soffit screens to sit in the same piece. I put 3/8 treated plywood cut in 12" x 8' lengths on the outside of the insulation, then the tin to cover and attach to the shop.....turned out really nice I think

Got the lower 9 feet wrapped with help from coffeeaddict...

Picked up the first large order for the electrical and have started to lay out receptical box's and lighting locations and run a bit of wire.

Then had a bunch of custom 26 ga tin bent up for the shop, lower trim in black to cover the ridgid insulation on the foundation, trim around the garage doors is in white, and one last area in black to cover the facia boards and also extend down a bit to allow the soffit screens to sit in the same piece. I put 3/8 treated plywood cut in 12" x 8' lengths on the outside of the insulation, then the tin to cover and attach to the shop.....turned out really nice I think

The following users liked this post:

edwinsmith (09-29-2018)

#108

Registered User

Thread Starter

I'm baffled by this photo post. Why is there wood contacting grade ? Even pressure treat (today's garbage) will fail with constant exposure to soil moisture. It does look very nice, although you have it flashed incorrectly. The verticals on the tin need to be installed behind the WRB so that it's a "rainfall pattern, otherwise moisture or water that gets in behind the WRB will ultimately go "BEHIND" the tin, and rot from behind, or expand when frozen. Always think "WATERFALL" when orienting any types of flashing or penetrations.

I have 2" ridged foam insulation on the outside of the foundation and it was already getting damaged and cooked by the sun and would probably start flaking away in a couple years. So thought was to protect it with the 3/8 plywood, and the flashing to keep water and material from getting behind it. I can adjust the vapour barrier to fall on the outside of the flashing easy enough.

#109

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,769

Received 1,637 Likes

on

1,112 Posts

I'm assuming the WRB is the house wrap?

I have 2" ridged foam insulation on the outside of the foundation and it was already getting damaged and cooked by the sun and would probably start flaking away in a couple years. So thought was to protect it with the 3/8 plywood, and the flashing to keep water and material from getting behind it. I can adjust the vapour barrier to fall on the outside of the flashing easy enough.

I have 2" ridged foam insulation on the outside of the foundation and it was already getting damaged and cooked by the sun and would probably start flaking away in a couple years. So thought was to protect it with the 3/8 plywood, and the flashing to keep water and material from getting behind it. I can adjust the vapour barrier to fall on the outside of the flashing easy enough.

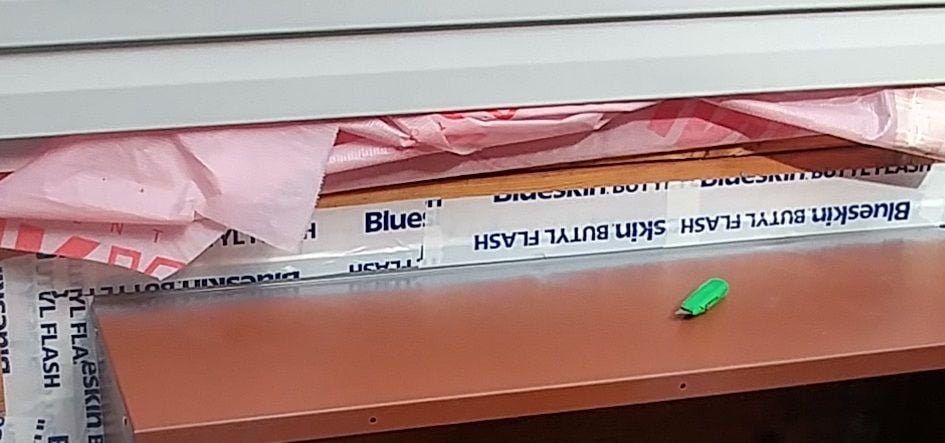

Don't remove anything. Take your razor, and cut the WRB (weather resistant barrier)

directly above the top of the vertical flashing. Let it loose. Use peel and stick and apply the peel and stick tape rubber tape to the sheathing of the building behind the WRB, and over the top of the flashing. This creates your "waterfall" pattern, allowing any moisture that gets, either on the WRB, or the building sheathing to expel itself back out onto the fact of the vertical flashing.... and out to daylight.

directly above the top of the vertical flashing. Let it loose. Use peel and stick and apply the peel and stick tape rubber tape to the sheathing of the building behind the WRB, and over the top of the flashing. This creates your "waterfall" pattern, allowing any moisture that gets, either on the WRB, or the building sheathing to expel itself back out onto the fact of the vertical flashing.... and out to daylight.I have used Vicor, I've used protecto-wrap, and I've used other brands of peel and stick window / door tape, but NOTHING works as good as Blueskin Waterproof tape.

Use a J-roller to seat it once you've placed it by hand. Do not leave exposed to sunlight, as it will fail over time. It's designed to be behind trim, so raise it up off of the alum capping so that when it's applied, and covered, you can't see it behind the siding. Do short lengths at first. The stuff sticks to almost anything, including itself, but will not release once it's stuck.

The pink WRB in this photo was cut about 1/4" off of the top of the housing below. It was then taped "intermittently" to the blueskin with tyvek tape or more smaller pieces of blueskin. It was not taped completely shut. Again, this allows any moisture that gets behind the pink WRB to flow out from behind , on top of the blueskin, on top of the flashing and out to daylight.

The following users liked this post:

edwinsmith (09-29-2018)

#110

Registered User

thought was to protect it with the 3/8 plywood, and the flashing to keep water and material from getting behind it

I believe T is absolutely correct in his comments regarding the details of tying your "WRB" into your drip cap.

FWIW, in our cap designs we would incorporate a slope of no less 1/4:12 in the horizontal, and a "kick" in the drip edge bringing the line a minimum of 3/16 from the face (the foundation wall in this case) plane.

Please forgive the unsolicited comments after the fact.

Alec

The following 3 users liked this post by Alec:

#111

Floors looking good! Who did you get the sealant through? I should probably order it sooner than later!

My house was built in 2015, has pressure treated plywood, no signs of wear although nothing lasts forever(should last 30+ years). You're lucky you don't really have to worry about water on your ground with your set up. You could daylight your house and shop gutters to the ravine in no time...I'm sure you'll keep the path between the house clear in the winter which just leaves the ravine side and backyard. Non issue IMO...I've got a good dump truck guy if you need any more ground material...That beautiful sandy loam is gonna get muddy! LOL, always something... I detached my hoses tonight, supposed to be -3?!?

My house was built in 2015, has pressure treated plywood, no signs of wear although nothing lasts forever(should last 30+ years). You're lucky you don't really have to worry about water on your ground with your set up. You could daylight your house and shop gutters to the ravine in no time...I'm sure you'll keep the path between the house clear in the winter which just leaves the ravine side and backyard. Non issue IMO...I've got a good dump truck guy if you need any more ground material...That beautiful sandy loam is gonna get muddy! LOL, always something... I detached my hoses tonight, supposed to be -3?!?

#112

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,769

Received 1,637 Likes

on

1,112 Posts

Thanks Alec

I've been installing doors and windows for 34 years now. I used to install them without thought for proper flashing techniques, but I eventually learned, after removing thousands of doors, where the commonality was observed regarding rot, and sub structure damage. I read lots of trade manuals, and magazines as well. I'm at the point where I never receive callbacks for water infiltation at the door/ structure juncture. I engineer every install to return moisture back to daylight.

I agree with you regarding the frost heave issue there. If that plywood cover doesn't descend all the way down below the frost line, mechanical freeze thaw cycles will ultimately push it upwards and rip apart that nice new flashing cap.

Not in any way bashing TC's work. I am only telling him of my experiences because I care about the longevity of his project.. This is not An internet beat down. I can post photos of heaving damage I've encountered over the years if you wish (@TC), but I think you get the idea.

I've been installing doors and windows for 34 years now. I used to install them without thought for proper flashing techniques, but I eventually learned, after removing thousands of doors, where the commonality was observed regarding rot, and sub structure damage. I read lots of trade manuals, and magazines as well. I'm at the point where I never receive callbacks for water infiltation at the door/ structure juncture. I engineer every install to return moisture back to daylight.

I agree with you regarding the frost heave issue there. If that plywood cover doesn't descend all the way down below the frost line, mechanical freeze thaw cycles will ultimately push it upwards and rip apart that nice new flashing cap.

Not in any way bashing TC's work. I am only telling him of my experiences because I care about the longevity of his project.. This is not An internet beat down. I can post photos of heaving damage I've encountered over the years if you wish (@TC), but I think you get the idea.

The following 3 users liked this post by NJTman:

#113

Registered User

Thread Starter

Thank you for your comments and experiences Tman and Alec.....appreciate it! The movement of the plywood, or other material due to frost heaving never entered my thoughts.... I guess I can monitor it over this winter and see what happens and if there is evidence of movement then will rethink my design before next winter.

I guess I can monitor it over this winter and see what happens and if there is evidence of movement then will rethink my design before next winter.

I guess I can monitor it over this winter and see what happens and if there is evidence of movement then will rethink my design before next winter.

I guess I can monitor it over this winter and see what happens and if there is evidence of movement then will rethink my design before next winter.

#114

Registered User

Thread Starter

Floors looking good! Who did you get the sealant through? I should probably order it sooner than later!

My house was built in 2015, has pressure treated plywood, no signs of wear although nothing lasts forever(should last 30+ years). You're lucky you don't really have to worry about water on your ground with your set up. You could daylight your house and shop gutters to the ravine in no time...I'm sure you'll keep the path between the house clear in the winter which just leaves the ravine side and backyard. Non issue IMO...I've got a good dump truck guy if you need any more ground material...That beautiful sandy loam is gonna get muddy! LOL, always something... I detached my hoses tonight, supposed to be -3?!?

My house was built in 2015, has pressure treated plywood, no signs of wear although nothing lasts forever(should last 30+ years). You're lucky you don't really have to worry about water on your ground with your set up. You could daylight your house and shop gutters to the ravine in no time...I'm sure you'll keep the path between the house clear in the winter which just leaves the ravine side and backyard. Non issue IMO...I've got a good dump truck guy if you need any more ground material...That beautiful sandy loam is gonna get muddy! LOL, always something... I detached my hoses tonight, supposed to be -3?!?

#115

Thanks NJ, legit concerns no doubt! Thanks TC, yea I was thinking the same. Something more like an oil on wood rather than a polyurethane. I will have to think about it, framing started today so I still have a few weeks...let me know what you think after your first oil drop hits it. I'll be suprised if I'm on time for snow

#116

Registered User

Thread Starter

Last week I got most of the outside work done around the shop, more grading and packing, and got gravel put down around the outside of the shop and up to the main door so I can now drive into the shop.

Well I pulled Patches into the shop this evening to do an oil change, 345K km's and time to switch to the Rotella Synth 5W40 for the winter, and a few other things, gotta say nice to have an enclosed space to work on things....even if there is still no power or heat. But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.  I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

Well I pulled Patches into the shop this evening to do an oil change, 345K km's and time to switch to the Rotella Synth 5W40 for the winter, and a few other things, gotta say nice to have an enclosed space to work on things....even if there is still no power or heat.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.  I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

The following 4 users liked this post by thrashingcows:

#117

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,769

Received 1,637 Likes

on

1,112 Posts

That sucks.....

Was it waterbased ?

If so, then I too would stay away from it.

Was it waterbased ?

If so, then I too would stay away from it.

#118

Last week I got most of the outside work done around the shop, more grading and packing, and got gravel put down around the outside of the shop and up to the main door so I can now drive into the shop.

Well I pulled Patches into the shop this evening to do an oil change, 345K km's and time to switch to the Rotella Synth 5W40 for the winter, and a few other things, gotta say nice to have an enclosed space to work on things....even if there is still no power or heat. But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.  I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

Well I pulled Patches into the shop this evening to do an oil change, 345K km's and time to switch to the Rotella Synth 5W40 for the winter, and a few other things, gotta say nice to have an enclosed space to work on things....even if there is still no power or heat.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.

But I did discover that the sealer/clear coat I put on the shop floor is not as advertised.  I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

I specifically asked if this sealer was chemical/gas/oil resistant and was told YES by the sales representative......well it might be oil resistant (cleaned up a few drops no problem) but a bit of brake clean and it gets all sticky and tacky. Oh well guess I won't be using this product again. Also dug my 3' deep trench from the house out to the shop for the main power line, and I'm going to try and get most of the electrical roughed in on my days off.

#119

Registered User

Thread Starter

The following users liked this post:

thrashingcows (10-14-2018)