opps! used grease on rear axle bearings

#1

Unless it's untaxed, then it's red.

Thread Starter

Join Date: Aug 2009

Location: Damascus MD

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

opps! used grease on rear axle bearings

Ok so it looks like another lesson learned the hard way, I used kendall super blue axle grease when I put my bearings in my rear axle. Now I find out I should have just used gear oil? I'm sure its all flushed out of the bearings and mixed in with the rear gear oil. I would like to know if I should worry about my limited slip diff clutch being contaminated by all that grease.

Should I drain and refill?

Also,

Where are people finding brake boosters that are not remans. I've been looking and checked: napa, pep boys, car quest, advance, and rock auto, and nobody has new units.

Should I drain and refill?

Also,

Where are people finding brake boosters that are not remans. I've been looking and checked: napa, pep boys, car quest, advance, and rock auto, and nobody has new units.

#2

1st Generation Admin

I wouldn't sweat over it as grease is nothing more than lube-oil with a thickener (soap, talc, etc). Packing the bearings as such is one thing, filling (packing) the bearing housing like one would the front bearings might be something else.

I guess my biggest concern would be if the normal lube oil could get into the bearings, thus eventually diluting the grease and eventually going back to normal operation.

Having said that, I suppose I would go ahead and open it back up, flush out what grease I could from the bearings and refill the hog's-head with fresh oil and friction modifier.

That friction modifier may in fact conflict with the grease. That may in turn, goof around with the clutches of the limited-slip assembly (if you have one).

I guess my biggest concern would be if the normal lube oil could get into the bearings, thus eventually diluting the grease and eventually going back to normal operation.

Having said that, I suppose I would go ahead and open it back up, flush out what grease I could from the bearings and refill the hog's-head with fresh oil and friction modifier.

That friction modifier may in fact conflict with the grease. That may in turn, goof around with the clutches of the limited-slip assembly (if you have one).

#3

Unless it's untaxed, then it's red.

Thread Starter

Join Date: Aug 2009

Location: Damascus MD

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

Ok then here is my plan. I am doing the 1 ton shoe this weekend, if there is grease on the bearings when I take the drums off I will clean it. If the grease has washed away I will change the fluid.

What friction modifier should I use? I have royal purple gear oil in there now

What friction modifier should I use? I have royal purple gear oil in there now

#4

Registered User

When I serviced may Dana 60 in the crewcab I couldn't find a definite answer to oil/vs grease for the axle bearings. So I decided to grease them anyway with Castrol high temp axle bearing grease, and then fill the diff with the appropriate fluid.

I had the rear drums off not long ago, after about a 10K miles, and there was still some soupy grease mixture around the bearings. I cleaned them up with some clean towels, filled the hub with more gear oil, (No grease this time) and put it all back together. Have not had any problems....but I don't have a LS in my Dana either.

If your doing the 3" brake upgrade and your still concerned, then I'd clean as best you can...without pulling the new rear seals...and then drain your fluid and start over. Maybe do another fluid flush in 6 months just to be sure you've cycled out all the potential grease from your housing.

I had the rear drums off not long ago, after about a 10K miles, and there was still some soupy grease mixture around the bearings. I cleaned them up with some clean towels, filled the hub with more gear oil, (No grease this time) and put it all back together. Have not had any problems....but I don't have a LS in my Dana either.

If your doing the 3" brake upgrade and your still concerned, then I'd clean as best you can...without pulling the new rear seals...and then drain your fluid and start over. Maybe do another fluid flush in 6 months just to be sure you've cycled out all the potential grease from your housing.

#5

Registered User

About a year ago I had a Cardone reman booster fail after less than a week in operation. Rather than go reman again, I decided to go new. Mother Mopar has discontinued the booster but my local Dodge dealer's computer showed about five units remaining on dealer's shelves. I ordered mine from a Dodge dealer somewhere in Kansas and got a great price. Have your local Dodge dealer check his computer. Good luck.

#6

Registered User

Pack your wheel bearings for god sake! Too many rear axles I've been in without any signs of grease or oil and needed wheel bearings! I'm in the grease my wheel bearings camp, unlike Mr. BC  .

.

.

.

#7

Registered User

Join Date: Feb 2008

Location: north woods of Michigan

Posts: 550

Likes: 0

Received 0 Likes

on

0 Posts

now the amount of grease if overdone might be a bad thing.

now the amount of grease if overdone might be a bad thing.In other words you did it right don't second guess yourself.

Trending Topics

#8

No , eh?

Last edited by BC847; 03-02-2012 at 08:31 PM. Reason: Language

#9

1st Generation Admin

Well I'll be daggum! I learn something every day.

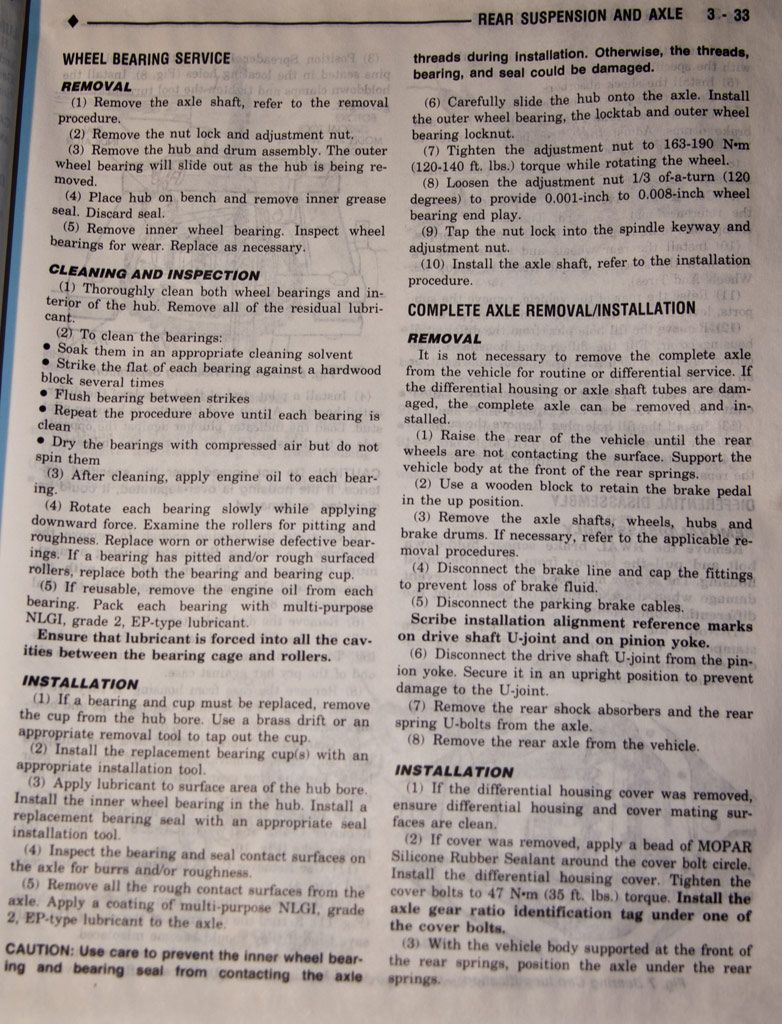

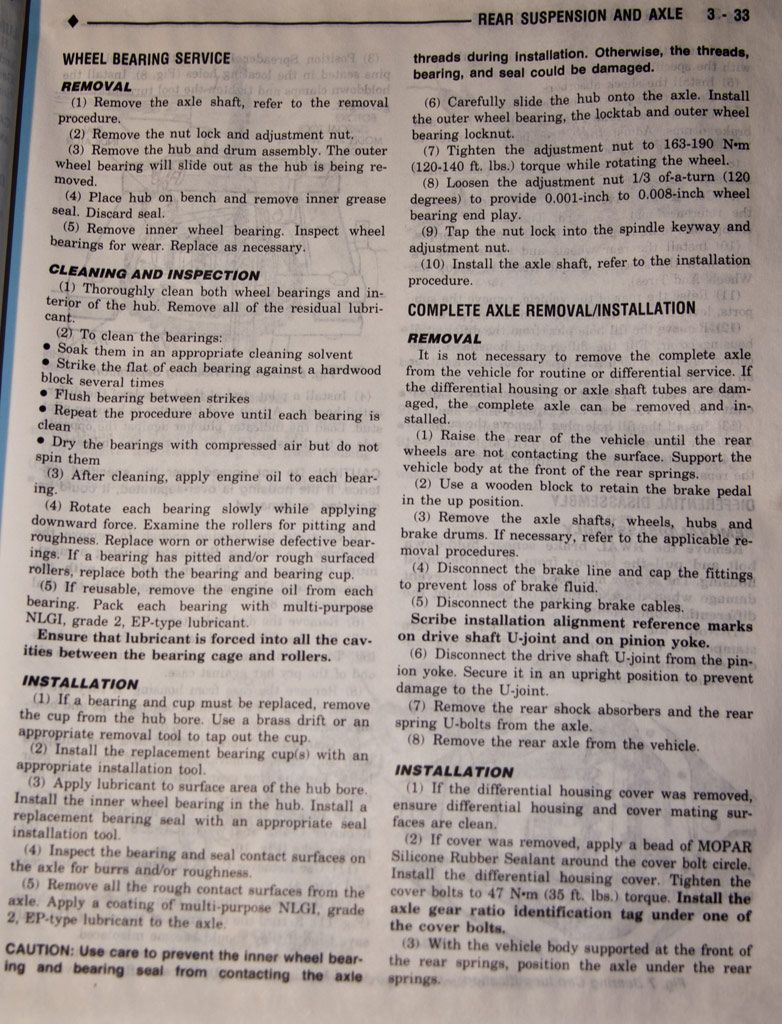

(From the '93 FSM):

It looks like you're OK then, #2isgreen. When goofing around with my rear-axle bearings, I've always completed the work by placing the truck on a steep incline so as to ensure axle lube-oil ran over and into the bearing cases.

Thanks for the correction folks.

(From the '93 FSM):

It looks like you're OK then, #2isgreen. When goofing around with my rear-axle bearings, I've always completed the work by placing the truck on a steep incline so as to ensure axle lube-oil ran over and into the bearing cases.

Thanks for the correction folks.

#10

Unless it's untaxed, then it's red.

Thread Starter

Join Date: Aug 2009

Location: Damascus MD

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

Update:

I got into things tonight and found that life works in funny ways. Yes I had a squeak and so I thought a wheel cylinder wasn't releasing right, but what I found was very unexpected. Keeping in mind that I did a full brake job about 4 months ago (minus wheel cylinders) I was surprised to see one of the "J" clips that hold the "hold down spring" was TOTALLY gone. I guess the little flared head came off. There was absolutely no sign of it other than the metal filings everywhere. This caused the hold down spring to free roam inside the drum for goodness knows how many miles. The brake adjustment wheel is destroyed from impact with the hold down spring and the shoe is ruined from riding out of alignment. Atleast the shoe is only worth a $13 core for my sweet new 3" set up. Back to napa tomorrow for a spring kit and hopefully I can get the loaded booster bled and installed.

Ps the hardware kit I used 4 months ago was from rockauto.

Thank you all for your help, I can return my gear oil in the am and save some money.

I got into things tonight and found that life works in funny ways. Yes I had a squeak and so I thought a wheel cylinder wasn't releasing right, but what I found was very unexpected. Keeping in mind that I did a full brake job about 4 months ago (minus wheel cylinders) I was surprised to see one of the "J" clips that hold the "hold down spring" was TOTALLY gone. I guess the little flared head came off. There was absolutely no sign of it other than the metal filings everywhere. This caused the hold down spring to free roam inside the drum for goodness knows how many miles. The brake adjustment wheel is destroyed from impact with the hold down spring and the shoe is ruined from riding out of alignment. Atleast the shoe is only worth a $13 core for my sweet new 3" set up. Back to napa tomorrow for a spring kit and hopefully I can get the loaded booster bled and installed.

Ps the hardware kit I used 4 months ago was from rockauto.

Thank you all for your help, I can return my gear oil in the am and save some money.

#11

Registered User

Join Date: May 2008

Location: Lake Placid FL USA

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Well I'll be daggum! I learn something every day.

(From the '93 FSM):

It looks like you're OK then, #2isgreen. When goofing around with my rear-axle bearings, I've always completed the work by placing the truck on a steep incline so as to ensure axle lube-oil ran over and into the bearing cases.

Thanks for the correction folks.

(From the '93 FSM):

It looks like you're OK then, #2isgreen. When goofing around with my rear-axle bearings, I've always completed the work by placing the truck on a steep incline so as to ensure axle lube-oil ran over and into the bearing cases.

Thanks for the correction folks.

#13

Registered User

If at all possible, I always "pack the bearing even though it is in an oil-bath"

And, you can never go wrong with Kendall Super Blu L427; it should be against the law to use anything else.

And, you can never go wrong with Kendall Super Blu L427; it should be against the law to use anything else.

#14

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,770

Received 1,637 Likes

on

1,112 Posts

I"ve read a bunch of different articles and threads about this very subject. The grease is there because most of us aren't going to spend the time making sure the gear lube reached the bearings / hubs when pulling an axle, and the writers of the service manuals don't want bearing failures based upon instructions they write.... so..

What I do.... and I'll be doing this this week, as I have to change my gear oil for it's annual "just before the snow season change"... is relatively simple.

After refilling the diff, I put a jack under the once side of the axle, and jack it up high as I can get it. I let it sit for about 10 minutes or so. I remove the jack, and put it on the other side, raising up the truck on the opposite angle for about 10 minutes.. This puts gear oil into the other hub. I drop the jack down level, wait about 10 minutes, and check the level. I add if necessary.

With the jack now under the center section of the axle, I lift the whole axle up and put jack stands under both sides, and lower it down onto the stands. I put a chock under the front wheels, and I start the truck. I put the truck in drive, and let the wheels spin for about 5 minutes. Sometimes I'll even rev it up a bit to get them moving, always being ready to hit the brakes if something odd happened. Turn the truck off.

Pull the jacks and stands and head to a large parking lot. Amsoil Tech help says that when you have a LSD rear axle, that it's helpful to go do a few "tight circle eights" in a parking lot to allow the clutches to separate, and get the new gear oil in between. Since Amsoil doesn't require any additives to their gear lubes, this is how they minimize chatter after changing your fluid. Amsoil has additives for clutches in all it's gear oils, so no extra is required.

Time consuming ? Yeah, but at least I know my bearings are oiled up good.

What I do.... and I'll be doing this this week, as I have to change my gear oil for it's annual "just before the snow season change"... is relatively simple.

After refilling the diff, I put a jack under the once side of the axle, and jack it up high as I can get it. I let it sit for about 10 minutes or so. I remove the jack, and put it on the other side, raising up the truck on the opposite angle for about 10 minutes.. This puts gear oil into the other hub. I drop the jack down level, wait about 10 minutes, and check the level. I add if necessary.

With the jack now under the center section of the axle, I lift the whole axle up and put jack stands under both sides, and lower it down onto the stands. I put a chock under the front wheels, and I start the truck. I put the truck in drive, and let the wheels spin for about 5 minutes. Sometimes I'll even rev it up a bit to get them moving, always being ready to hit the brakes if something odd happened. Turn the truck off.

Pull the jacks and stands and head to a large parking lot. Amsoil Tech help says that when you have a LSD rear axle, that it's helpful to go do a few "tight circle eights" in a parking lot to allow the clutches to separate, and get the new gear oil in between. Since Amsoil doesn't require any additives to their gear lubes, this is how they minimize chatter after changing your fluid. Amsoil has additives for clutches in all it's gear oils, so no extra is required.

Time consuming ? Yeah, but at least I know my bearings are oiled up good.